Discover Top Rice Milling Machine Manufacturers in China

For anyone looking for a rice milling machine in China, it may not be as simple as expected. However, that does not mean you cannot find a reliable rice mill machine manufacturer.

Opting to source from China-based manufacturers may help you shop for this equipment with less expense. Here is a comprehensive buying guide with 11 ways to find a rice milling machine manufacturer in China:

1. What Is Rice Milling Machine?

2. Rice Mills Machines Advantage?

3. What Different Types Of Rice Milling Machines?

4. How does a Rice Milling Machine Work?

5. How Much Is a Rice Milling Machine?

6. How Do We Choose A Reliable Rice Mill Machine Manufacturer?

7. Where are Rice Milling Machine Produce Base In China?

8. Where To Buy Rice Milling Machine In China?

9. Top 10 rice mill machine manufacturers in China

9.1 Hubei Fotma Machinery Co., Ltd

9.2 Zhengzhou Taizy Machinery Co., Ltd

9.3 Zhengzhou Hongjia Grain Machinery Co., Ltd

9.4 Shandong Kingrunda Machinery Co., Ltd

9.5 Victor farm machinery

9.6 Lushan Win Tone Engineering Technology Co., Ltd.

9.7 Hunan Sunfield Machinery Co., LTD

9.8 Tianmen Xianliang Machinery Co., Ltd

9.9 Hubei Bishan Machinery Co., Ltd

9.10 Henan Doing Mechanical Equipment Co., Ltd

10 Rice Milling Machine FAQ

11. Why Choose Huntersourcing As Your Rice Milling Machine Sourcing Agent?

1. What Is Rice Milling Machine?

A rice milling machine is a machinery used to depitter and husk in breaking down the rice grains into polished seeds. Rice milling involves various stages through which rice from the farm is taken through cycles that make it undergo some changes.

• Cleaning

The first process entails cleaning, hence the process of separating all the foreign bodies like stones and straw, among others, from the harvested paddy rice. This is normally done using sieves, aspirators, and de-stoners.

• Husking

Feeding the cleaned paddy rice into a husker or huller helps eliminate the outer husk layer. Operators can sometimes do that practically using rubber rollers, whereby the rice grains are rolled between them in such a way that they create friction on the outer layers of the grains. That way, the husk is removed.

• Paddy separation

The raw rice and a bran layer are two components of ripe cereal grain separated by a paddy separator. Brown rice will pass through another process as the separated paddy is prepared for husking.

• Polishing/whitening

The brown rice is then milled or pearled, depending on the type of rice, to take off the bran layers. Situations where one object rubs or scrapes against another are most common for achieving such a result. The result is white rice.

2. Rice Mills Machines Advantage?

The use of rice milling machines has several benefits when it comes to rice production, such as increasing the speed of milling, among other benefits. Other advantages are:

• Increased efficiency

Rice milling machines can mill large quantified batches of rice. They are much more efficient than hand milling methods since they quicken the milling process.

• Higher yield

Current rice milling devices are intended to ensure a high yield by trying to incorporate a method that reduces the breaking of grains and thus preserves more kernels of rice.

• Consistency and quality

Milling machines ensure all the rice grains have the same qualities and appearance. This is essential in addressing market demand and consumers’ preferences.

• Labor savings

By minimizing the use of labor, automation frees up labor capacity, lowers labor expenses, and minimizes mistakes that could result from human intervention. All these can ultimately drive productivity and reduce expenses.

3. What Different Types Of Rice Milling Machines?

Several types of rice milling machines exist in the market, and each of them is designed to carry out a specific or several functions in the milling process of paddy rice to produce white rice.

• Grain dryer

The grain dryer is a machine that enhances the quality of the harvested grains by trying to remove as much moisture as possible for it to be safe for storage and more processing.

• Paddy cleaner

A paddy cleaner is an agricultural tool that provides the necessary cleaning of paddy rice. The cleaning reduces the bugs and other contaminants in rice before it is packaged and sold to consumers.

• Rice destoner

The machine is used to mush or sift out large particles of stones, clods, and other heavy substances from the rice before more elaborate milling processes.

• Rice huller

A rice huller is a primary machine in the rice milling process as it is primarily used in removing the hull or husk from rice grain. The machine strips off the outer husk or hull from the rice grain leaving brown rice kernel only.

• Paddy separator

A paddy separator is a machinery employed in the processing of rice to sift between un-helped paddy rice, commonly referred to as rough rice, and brown rice. The machine is used after hulled rice to sort out the stream of un-husked paddy rice and brown rice from each other.

• Rice thickness grader

A rice thickness grader grinds milled rice grains concerning their thickness or width. The equipment is a sieve for categorizing the milled grains of rice according to either thickness or width. It usually has one or more than one screen with different screen gaps or mesh sizes.

• Rice whitener

A rice whitener, on the other hand, is regarded as one of the major machines in the rice milling process. After the first milling, which aims to remove the outer husk to get the brown rice, there is the rice whitener, which whitens the rice with the help of removing the dermatological layer.

• Rice grader

A rice grader, a rice milling equipment, is a machine that sorts out ‘milled’ rice grains according to their size, shape, and quality. This is used after the rice has undergone the whitening or polishing process with a view of sorting out the milled rice grains in terms of grades or categories. The grader commonly incorporates several sieves or screens of the respective mesh size.

• Rice polisher

A rice polisher is another important piece of equipment used in the rice milling process. It is sometimes called a rice polishing machine or rice whitening machine. It is used after the hull and white boiling processes, which is to remove the outer coating and bran layer.

• Rice length grader

A rice length grader is a piece of equipment employed in rice separation during the milling process for the classification of milled rice grains by length. The machine is used for sorting milled rice grains based on length so that it is placed in their appropriate category.

• Color sorter

A color sorter is an exceedingly futuristic mechanical contraption employed in rice milling to separate grains depending on their shade. The machine incorporates specialized optical techniques for the identification of the barbarously discolored rice grains to sort out defective ones, foreign matters as well as impurities.

• Rice packing machine

The use of a rice packing machine involves packaging rice in bags or any other packaging depending on the channels of distribution and marketing. The machine mechanizes the workflow of using a platform scale to weigh, the packaging section to fill bags or containers with rice, and the sealing section to seal those bags or containers.

• Blower & airlock

A blower and airlock system are the most commonly used techniques, especially for handling and moving rice grains and other materials in the processing plant.

• Elevator & conveyor

Elevators and conveyors can largely be described as tools that play an important role in transporting rice grains and other items in mills that deal with the milling of rice.

• Innovative product

Both elevators and conveyors have important functions in aspects like the productivity, efficiency, and safety of rice milling. They facilitate the efficient flow of material with the least amount of handling by humans, loss of products, and quality degradation of the rice products during the flow through the various stages of the processing stream.

Rice mill machine parts

A rice milling and polishing machine consists of different parts, and these parts play great roles in processing rice in the rice milling process. Here are some essential parts commonly found in a portable rice milling machine:

• Hopper: Hopper is where the operator places unprocessed paddy rice to be processed.

• Huller: The huller effectively strips the grains of the outer husk layer to produce unhulled rice from brown rice.

• Whitener: It completes the removal of the outer layers of bran from the brown rice to produce white rice.

• Grader: A grader in a mini rice mill machine includes brands of different sizes, shapes, and qualities and separates them into grades of rice.

• Rollers or abrasive surfaces: Formerly incorporated in hullers, whitening machines, and polishers to eliminate the outer skin and layer of bran by friction in the rice milling industry.

• Screens or sieves: These are parts of an electric rice mill machine. They are deployed in graders or length graders to sort out rice grains according to size.

• Frame and housing: Serves as the primary frame and shield for the interior components and gadgets of a home rice milling machine.

4. How does a Rice Milling Machine Work?

The rice milling machines play a vital role in the machinery process where the un-edible raw rice grains are converted into rice. The machine works in the following ways:

• Cleaning and destining

The first step in rice processing is the way the rice grains are sieved and washed to get rid of undesirable particles such as stones, dirt, and other unwanted particles.

• Husking

The process involves the outermost layer of the rice grain, also known as the husk or hull being removed.

• Paddy separation

After husking, there is another process called ‘separating’ where the husk of the rice grain or the ‘paddy’ and the grains have to be separated.

• Whitening or polishing

The outer brown layer, outer bran coat, and inner germ, which make up a part of the rice grain, are either partially or eliminated to produce white rice. Operators achieve this by taking the grains through an abrasive roller or by friction if it is on the polisher.

5. How Much Is a Rice Milling Machine?

The rice mill machine price depends on other factors like the rate of milling, type of milling, brand, and location where it is bought from.

When it comes to rice mill prices, small machines range from as little as $500 to as high as several thousands of dollars. Small rice milling machines, on the other hand, can cost below a thousand dollars for low-capacity machines with basic functions.

6. How Do We Choose A Reliable Rice Mill Machine Manufacturer?

It is essential to select the manufacturer that supplies a rice mill machine that is reliable to meet the rice milling processes and outcomes that you expect. These steps are useful in choosing a manufacturer:

6.1 Products and accessories

It is necessary to consider not only the line of primary products but also the availability of additional accessories and related machinery. Confirm if the manufacturer offers a range of accessories and attachments usable in the rice mill machines to make them more useful and flexible.

6.2 Technical support and training

Expert advice and guidance are some of the most important considerations to be made while selecting a rice mill machine manufacturer. That entails help in installation, problem shooting and also dealing with any complications that a company, organization, enterprise, or company may encounter while using it.

Confirm whether the manufacturer provides training to your workers at the business facilities. By utilizing on-site training, your staff will not only receive practical training but also specific for your equipment and working conditions, which improve knowledge and skills.

6.3 R&D

Skills in Research and Development should be given due consideration when selecting a manufacturer of rice milling machines. A manufacturer with adequate research technology can come up with new approaches to milling the grains that can bring efficiency, quality, and sustainability into the business. These may result in innovations. The innovations may help you to have a competitive advantage in the market.

Such an approach makes it possible for manufacturers to meet the customer’s needs by exercising their R & D competency levels on rice mill machines.

6.4 Rice mill Process flow and Plan

Location and planning for your rice mill, along with its process flow, directly impact the decision when choosing a rice mill machine manufacturer.

The current and the future production capacity and demand are important factors. You will need to decide on the capacity per day or week of your rice mill and the type of rice you intend to mill (for example, long grain, short grain, parboiled, etc).

6.5 Coordination with Contractors

It is important to set down communication channels with the contractor right from the start. Explain and detail all the specifications and the preferable time for the procurement of rice mill machines.

6.6 Installation and commissioning

Both installation and commissioning are processes that form part of the implementation of rice mill machines. Select a manufacturer who allows their team to install the system for you. Operators who understand the entire setup of the equipment can be useful in appropriately handling the equipment. That reduces the possibility of making wrong choices during installation.

6.7 Support and monitoring of the rice mill project progress

Ongoing support and monitoring of the rice mill project’s progress are critical aspects of ensuring its success.

The manufacturer should also report progress made in the manufacture, shipping, and delivery of the rice mill machinery to the project team. That also ensures compliance with best practices in procurement so that any concerns with the suppliers or any doubts concerning the supply of goods and services can be rectified immediately.

6.8 Run & commission the rice mill plant

The processes involved in the operation of a rice mill plant from a newly constructed plant to the actual commissioning must be adequately planned to enhance the efficiency of the plant. Ensure that the area allocated for the project has enough space, good transport networks, and resources like water and electric power.

6.9 Training operating staff

Ask the manufacturer what training courses, if any, are offered for the working of the rice mill machines. Professional manufacturers should be able to ensure proper training with their employees, and this will involve teaching them how to use the equipment for the safest and most effective procedures.

6. 10 After-sale service

It is crucial to ascertain that the manufacturers can provide timely and adequate technical support that would be required to deal with any problems or queries that the rice mill machine might present. That encompasses installation, operations, maintenance, and diagnosing problems and their solutions..

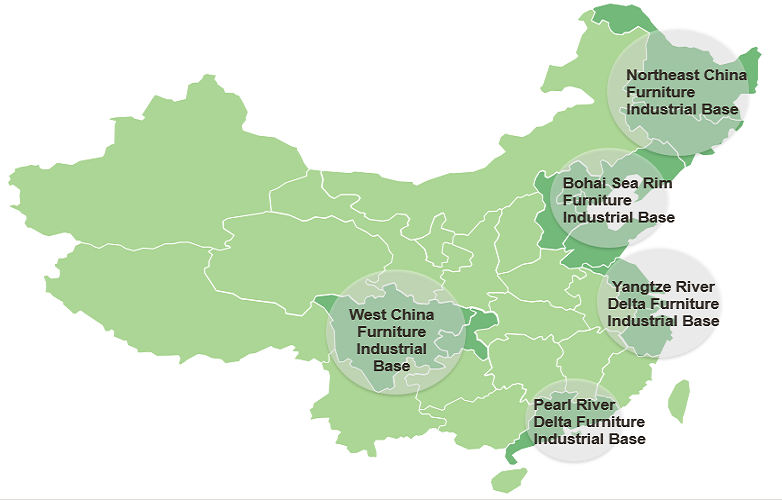

7. Where are Rice Milling Machine Produce Base In China?

Some of the major manufacturing bases include:

7.1 Wuhan, Hubei

Wuhan has all the key characteristics that make it a dominant player in this industry – geographical advantage, adequate industrial base, and trained manpower. Wuhan contains large manufacturing firms dedicated to the development, assembly, and sale of numerous forms of rice milling machines for both domestic and export purposes.

7.2 Zhengzhou, Henan

The other area that experienced a high production of rice milling machines is Zhengzhou City in the Henan province of China. Henan province is among the largest provinces in China covering a large extent of agricultural land. As a result, Zhengzhou, its capital, is known to have a well-developed industrial section that deals with agricultural tools such as rice milling machines.

7.3 Qingdao, Shandong

Qingdao boasts of a strong agriculture machinery market. Buyers can find several local manufacturers in Qingdao.

7.4 Dongguan, Guangdong

Dongguan is situated in Guangdong Province. It has a well-developed manufacturing sector with industries such as electronics, textiles, and machinery.

8. Where To Buy Rice Milling Machine In China?

If you’re interested in purchasing rice milling machines, you can access them in different ways in China, either through the Internet or personally. Here are some options:

1. alibaba.com

2. made-in-china.com

3. dhgate.com

4. globalsources.com

5. aliexpress.com

6. chinabrands.com

7. Huntersourcing -China sourcing agent

9. Top 10 rice mill machine manufacturers in China

Many manufacturers in China specialize in rice milling machines and their related equipment. These rice milling companies often provide equipment suited to different-sized rice processing operations.

The following rice milling companies are some of the top-rated suppliers based in China:

9.1 Hubei Fotma Machinery Co., Ltd.

Hubei Fotma Machinery Co., Ltd. is a top-rated factory mainly dealing in agricultural machinery. The paddy milling machine is one of the products it produces.

Established in Hubei province, Fotma has gradually attracted recognition due to its specialization in agriculture equipment, rice mill machines included.

It is your best supplier when you want to buy the best rice mill machine that suits your needs.

More details are listed at https://www.fotma.com/.

9.2 Zhengzhou Taizy Machinery Co., Ltd

Zhengzhou Taizy Machinery Co., Ltd. is a company that focuses on agricultural equipment. They are normally launching rayon products with new technologies that help enhance the efficiency of the rice processing system as well as increase yield.

The factory has carved out for itself a reputation as an industry player in the Agricultural machinery arena that can help enhance rice processing manufacture and business around the globe. Visit https://www.agriculture-machine.com/ for details.

9.3 Zhengzhou Hongjia Grain Machinery Co., Ltd

Zhengzhou Hongjia Grain Machinery Co., Ltd. deals in rice milling equipment for sale with a complete rice milling plant, rice husking machine, rice polishing machine, rice separator, and paddy milling machine. All their machines target all the processes that are likely to be involved in rice processing, aimed at producing quality rice.

The company builds highly specialized machinery products for its customers. They also always spend resources on innovation and enhancements of the products and services available. There are standards and quality control that the company observes and various accredited international certifications for their products. The supplier sells its rice milling machines at https://www.ricemillingmachinery.com/

9.4 Shandong Kingrunda Machinery Co., Ltd

Shandong Kingrunda Machinery Co., Ltd. is a prominent producer of rice milling machines and other native grain processing machinery located in Shandong Province, China.

At the same time, it is important to note that the company has prevailed among the leaders of the industry due to its dedication to superior quality and the constant search for novelties.

You can find the full information and many other books at https://www.beanpeelingmachine.com/.

9.5 Victor farm machinery

Victor Farm Machinery presents a prospect of mini rice mills, combined rice mill plants, and large-scale rice milling equipment.

Their products are intended to suit mills from small to big rice millers, depending on their capacities. These products are listed at https://www.cornmachine.com/..

9.6 Lushan Win Tone Engineering Technology Co., Ltd.

Lushan Win Tone Engineering Technology Co., Ltd. manufactures and supplies various types of rice milling machines. Besides mini rice mills, the supplier deals in complete sets of rice mill equipment, paddy huskers, rice finishers, and rice separators.

They specialize in systems used in rice production as Milling and Parboiling equipment to increase production rate and gains.

Other than steaming and milling of rice, the company deals in the production of machines used for processing other grain products, including maize, wheat, and beans, among others, making it a valuable player in the grains processing industry. Visit http://www.wintonemachinery.com/ for more details.

9.7 Hunan Sunfield Machinery Co., LTD.

Hunan Sunfield Machinery Co., Ltd. deals in several rice milling machines. These include complete rice milling plants, rice hulling machines, rice polishing machines, and rice graders.

The equipment they bring for milling is flexible for both established Rice processing ventures and nano–ventures. Visit https://www.sunfieldam.com/ to buy a mini rice mill or any other milling rice machine that catches your eye.

Tianmen Xianliang Machinery Co., Ltd. is one of the best companies that manufacture rice milling and agricultural machinery. Established in Tianmen City, Hubei Province in China, the company has gradually grown significantly into the competitive industry due to its hard work on the supply of quality, new ideas, and excellent services to clients.

By using the company’s rice milling technologies, one can access the complete rice milling plant, rice miller, rice polisher, rice grader, and rice separator machine. Information regarding the company is well presented on the internet mainly at the website: https://www.xlricemill.com/.

9.9 Hubei Bishan Machinery Co., Ltd.

Hubei Bishan Machinery Co., Ltd. a professional manufacturer, has engaged in producing rice milling and other agricultural machinery.

It provides a complete solution for milling rice in its different capacities, from a complete rice milling plant to specific machinery such as a rice huller machine, rice polisher, and rice grader.

Their products focus on processing rice and have aspects of efficiency and effectiveness in the handling of rice production. Visit https://www.bishanricemill.com/ to place your orders.

9.10 Henan Doing Mechanical Equipment Co., Ltd

Henan Doing Machinery is a leading manufacturer of various varieties of rice milling machines, including rice mill plants, rice husking machines, rice polishing machines, and rice sorters.

Machinery in their process is aimed at increasing the flow rate and efficiency of rice processing machines and businesses. Find more details of this company at http://www.ricemillmachine.com/

10 Rice Milling Machine FAQ

Here are some frequently asked questions (FAQ) about rice milling machines:

10.1 How to set up a rice mill?

Here’s a general guide on how to set up a rice mill:

• Market research

Conduct market analysis to determine the quantity and quality of the rice market in your region including your targeted customers. Conduct a competitive analysis and evaluation of the prospect of developing a rice processing plant in the identified location.

• Business plan

Prepare a clear business plan that includes your goals and aims, choice of clientele, proposed price range, marketing techniques, your estimated income and expenditure, and any potential problems and solutions regarding the functioning of your business.

• Location and facility

Select a proper plot for investment in a rice mill that encompasses the raw materials near the production plant, transportation facility, and utility services.

• Rice milling equipment

Purchase quality milling machines that suit your operations depending on your company’s capacity.

• Raw material sourcing

Develop and ensure a steady supply of paddy rice (unmilled rice) for the company. You can source the paddy rice from the farmers, wholesalers, and regions growing rice.

• Staffing and training

Ensure that you hire personnel who are professional and experienced with operating the equipment in the rice milling business, handling managerial roles, and promoting the business.

• Marketing and promotion

Employ different forms of media communication, including internet advertising, social networking sites, exhibitions, and fairs, as well as joint marketing with local merchants. Emphasize the quality and new PC and USP of rice products that would make the consumer go for brand A over brand B.

10.2 Is the rice mill business profitable nowadays?

The possibility of earning good profits depends on several factors. These factors are the location of the rice mill business, the demand for rice in the region, the size of the mill, and the cost of inputs. Nevertheless, rice milling can be a lucrative business in most areas.

10.3 How do you get a rice mill license?

Here are some general steps you might need to take:

• Research local regulations

In the first step, it will be appropriate to collect information regarding the rules and regulations applicable to the rice milling business. If you are unsure of the kind of license you need, you can contact your local agricultural department or regulatory agency, which will inform you about any licensure requirements and rules or standards it has set for rice mills.

• Meet safety and sanitation standards.

Ensure that your rice mill has safety and sanitation measures to prevent workers, customers, or anyone in contact with the end products from any hazardous conditions. These can range from washing techniques, establishing protective tools, and other measures endorsed by the food safety rules.

• Submit license application

After completing the requirements for a rice mill license, ensure you can submit your application to the right regulatory agency. Make any payment that may be required for the license application fee or processing fee. Your next step may involve waiting until the regulatory authority processes and gives you a nod on your application.

10.4 How does the rice milling machine work

A rice milling machine, in simple terms, functions to remove different forms of coverings on rice grains: the husk, the bran, and the germ to yield polished white rice.

• Cleaning

The rice grains need to be cleaned so that any dirt, foreign substances such as stones, or any other impurities are washed off.

• Husking

In this step, the outer layers, which are brown and red, are also removed from the surface of the rice grain.

• Whitening

The whitening process involves the removal of the bran layer thus arriving at the polished white rice. This is often done by using abrasion by rough surfaces or rollers which apply pressure on the grains of rice to disentangle and separate the bran from the rice grains.

10.5 What are the various challenges of a rice milling business?

When people engage in the rice milling business, they are bound to encounter a few difficulties. Some of the common challenges include:

• Market fluctuations

Rice prices and demand for the different types, qualities, and brands of rice are affected by such factors as weather and climate changes and preferences and swings in consumer demand and global markets. Such volatilities and oscillations are sometimes difficult to forecast or manage; thus, challenging business practices may need to be introduced.

Sustaining high quality standards when dealing with the customers is very essential hence the need to remain consistent. However, controlling the quality of this consumption product right from the time it obtained the raw rice to the time it is packed requires a lot of scrutiny.

• Supply chain management

The process of handling raw rice and its supply, storage, and distribution channels can be challenging at times hence posing certain risks relating to supply chain management. Some of these factors include access to the crop, which may be affected by crop failure, lack of means of transportation, or storage, which also may be a problem.

10.6 What is the difference between ‘mill,’ ‘factory,’ and ‘industry’?

Here’s a breakdown of the differences between “mill,” “factory,” and “industry”:

Mill

Technically, a rice mill is a hardware system mainly used in the manufacture and Innovation of rice products whereby rice grains are processed into polished rice that is edible.

Factory

A factory is an establishment where materials are fabricated or produced using tools and human resources. Facilities, in general, encompass every production line and machinery needed for manufacturing goods from basic materials or parts. A mill is more specific in its operation in that it may involve only grinding mill or milling, while a factory is a large production facility to carries out operations of different industries.

Industry

Industry is an economic category that depends on manufacturing and selling various products or services. They include all forms of economic undertaking, whether manufacturing, agriculture, mining, construction, or services that engage in or belong to a specific field or area.

10.7 What are the disadvantages of a rice mill?

Here are some potential disadvantages of a rice mill:

• High initial investment

Rice milling involves the investment into some important assets such as machinery, infrastructure, and labor. Only a few people can afford the capital to do all that.

• Operational costs

The rice mill business requires constant costs incurred in maintaining the mill, energy costs, wages for employees, and cost of the raw material, which affects net revenue depending on price dips or volatility in the market.

• Complexity of operation

Each stage of the rice milling process comprises several finer sub-processes, which include cleaning, dehusking, whitening, polishing, and sorting, all of which depend on a skilled workforce and supervision to guarantee quality and timely production.

11. Why Choose Huntersourcing As Your Rice Milling Machine Sourcing Agent?

Here are five compelling reasons why you should consider Huntersourcing for your rice milling machine procurement needs:

• Expertise in the rice milling industry

We have an efficient team that interacts with our target market with a profound focus on the rice milling business, technologies, and supplies. Having such rich experience and vast knowledge, they are well-positioned to deal with various issues and make sure that we offer you the best services that are fashioned to fit your needs.

• Consulting services

Our team of industry experts is on hand to give informed consulting services and individual solutions that meet the needs and unique issues specific to your organization.

• Market research

The additional advantage of Huntersourcing is that it provides market research services to ensure that you are updated on the latest information. Relative to product development, Huntersourcing comprehensively studies market trends by quantification of the current and potential markets, and identification of competitors and customers’ preferences. Through their market and product research reports, it becomes easy to understand areas of value, potential risks, and ways of approaching them and exploiting them for maximum value.

• Supply chain management

Their supply chain management specialists concentrate on defining key strategies based on efficiency enhancement and cost-cutting approaches while working with you to design and develop every aspect of your supply chain needs. For supplier selection and price negotiation, Huntersourcing arranges and also coordinates its inventory management and supply chain logistics. That includes shipping & logistics and customs clearance. Their utilization of sophisticated technologies assists you in shortening lead times and reducing risk while boosting end-to-end supply chain performance.

• Factory audit

Using their seasoned audit team, manufacturing facilities, equipment, process, and quality control measures are subjected to a rigorous examination to ensure adherence to all relevant manufacturing standards and the client’s specifications. Through a thorough factory audit, any problems such as low-quality production processes, poor quality checks, or even professionalism can be avoided or even fixed. Asking for a sample is also part of the auditing we conduct.

Regarding quality, Huntersourcing has vigor policies in place that reduce the likelihood of blunders in production, design flaws, or any variation from the ideal level of performance.

Enhance your sourcing solution now with Huntersourcing for the perfect rice milling machines. Call us now and let us assist you in identifying the ideal brands and models.

Related Post

Furniture is a must for an office or a home. It is available at varying price points as Read more

Wood is extensively used in making furniture around the world. Wood can be molded in any shape or Read more

In the current market condition, a major portion of the world's consumption depends on China. The product range Read more

Contact Us Get Free Quote!

* Please kindly fill out the form for inquiry

* we will reply to your inquiry within 24hours