Cost-effective Wood Pellet Machine Suppliers in China

Wood pellet machines are a great way to save money and get the most out of your wood pellets. The best wood pellet machine will allow you to use fewer wood pellets, which means you can use less energy and reduce the greenhouse gas emissions your heating system generates.

1. What Is Wood Pellet Mill?

2. The Best Sellers Wood Pellet Machine

3. Wood pellet machine application

4. What Materials Can I Use to Make Pellets?

5. How Does A Wood Pellet Machine Work?

6. How To Make Wood Pellet Machine?

7. Where To Buy Wood Pellet Machine?

8. How To Choose The Right Pellet Mill?

9. How Do We Choose A Reliable Pellet Machine Manufacturer?

10. Wood Pellet Machine FAQ

10.1 How To Start A Biomass Pellets Project?

10.2 Can I make my own wood pellets?

10.3 Is it worth it to start manufacturing biomass pellets?

10.4 How to choose a biomass pelletizing machine?

10.5 Do all wood pellets and biomass pellets burn the same?

10.6 Do you know that biomass pellets are also called wood pellets?

11. Why Choose Huntersourcing As Your Wood Pellet Machine Sourcing Agent?

Summary

The best wood pellet machine from China will also be able to produce high-quality, consistent pellets from batch to batch. That is important because high-quality pellets mean fewer waste products in your heating system and more consistent heating for your home or business.

If you want a high-performance wood pellet machine, we have a buying guide for finding the best wood pellet machine from China.

1. What Is Wood Pellet Mill?

A wood pellet mill is a new machine that separates wood pulp into pulp and sawdust. You can use it in forestry, papermaking, building materials, and many other industries.

The main parts of a wood pellet mill are the separator, feeder, and compressor. The separator separates the wood pulp from sawdust by crushing them into small pieces. The crushed wood is fed into the feeder through a hopper or funnel. The feeder has a large capacity to supply enough raw material for the whole day of operation of the wood pellet mill.

The compressing system compresses air into wood pellets after it enters the machine through an entrance door at one end of the intake chamber. Air is compressed under pressure to create wood pellets with uniform size distribution (between 0.3-1mm), the moisture content is kept below 12%, and particle size distribution remains within acceptable limits for use in papermaking production lines.

2. The Best Sellers Wood Pellet Machine

The best wood pellet machine is an excellent investment for the home and can be used to produce heat and power. This article will look at some of the best-selling wood pellet machines on the market.

A wood pellet stove is ideal if you have a small space that needs heating in the winter or if you want to generate electricity from waste wood. Wood pellets are made from compressed sawdust and have a higher calorific value than other forms of fuel, such as coal or oil, which means they burn much hotter than their counterparts. They also release far less carbon dioxide into the atmosphere than fossil fuels.

There are many different types of stoves available on the market today. The most popular ones are boilers and gasifiers.

• Biomass pellet machine

A biomass pellet machine is a production line that can produce biomass pellets with different grades and specifications, such as softwood pellets, hardwood pellets, and mixed-wood pellets. It is mainly used to produce biomass pellets with different grades and specifications.

• Sawdust pellet machine

The sawdust pellet machine is a kind of modern wood pellet machine it can produce a high-quality finished product. The main body of the machine is made of stainless steel, which has a large capacity and good neutron shielding. The power consumption is low, and the running time is extended.

• Industrial wood pellet machine

The industrial wood pellet machine is this industry’s most advanced, high-tech, and powerful equipment. It can process various materials into pellets automatically without manual operation. Its significant energy saving and good performance allow it to be used in many fields, such as food processing and chemical production, papermaking, mining, metallurgy, etc., which can save a lot of labor costs. You can buy small or large wood pellet machines depending on your needs. It can be a flat die pellet mill or ring die pellet mill.

• Biomass pellet mill

The biomass pellet mill is used to grind the wood into the trash, then used as fuel. It has been widely used in the pulp and paper industries for years. The biomass pellet mill can grind any wood, including hardwood and softwood. The biomass pellet mill can process large quantities of wood at high speed in a short time. It is also easy to operate and maintain.

• Moblie Pellet Machine

The mobile pellet machine is equipped with a powerful engine and high-strength wheel, which makes the pellet machine move smoothly and efficiently. It mainly produces pellets for cement, bricks, other construction materials, etc. The pellet machine has a simple structure, low investment cost, and high productivity.

• Electric Pellet Machine

Electric wood pellet machine has several advantages, such as high efficiency and energy saving; it is suitable for small-scale heating coal and biomass processing production enterprises. The main technical parameters of electric wood pellet machines are as follows:

Power supply: electricity or diesel power supply

Material feeding method: manually feeding or automatic feeding

Material input rate: 0.5-1t/h

Temperature adjustment range: 0-300 ℃

Loading accuracy requirements: <0.2mm

• Electric Wood Pellet Machines

An electric wood pellet machine has two heating elements (one on each side) which create steam that turns into hot air inside the machine. That reaches temperatures up to 400 degrees Fahrenheit (200 degrees Celsius). The steam then passes through a filter where impurities are removed before being released into your house or business building through an insulated hose connected to an exhaust port at the back of the machine.

• Diesel Pellet Machine

The diesel pellet machine is a reliable type of pellet machine. They are commonly used because they can be controlled quickly and are much more potent than gas engines. They are also not as loud or smelly as other pellet machines. The downside to these machines is that they have a higher cost of operation than others, and it takes longer for them to heat up and cool down after use.

• Gasoline Pellet Machine

A gasoline pellet machine is a type of high-quality wood pellet production equipment with the same characteristics as small and large pellets, which can be used in many kinds of wood pellet production enterprises. The advantages of gasoline pellet machines include high efficiency, low consumption, fast operation, simple operation, easy maintenance, and so on.

• Integrated Wood Pellet Plant

The best seller’s wood pellet machine is the integrated pellet plant, which is the most convenient and practical. The main advantage of this type of plant is that it can produce a large volume of pellets at high efficiency. Compared with traditional wood pellet production, this plant has a relatively low investment cost, but its annual output makes up for its higher initial cost.

3. Wood pellet machine application

Wood pellet machine is a new high-efficiency, low-carbon-emission energy equipment that can produce energy, chemical and mechanical materials, and other industries. The main characteristics are compact structure, high production efficiency, and low operating cost.

The main technical parameters of the wood pellet machine are as follows:

Feeding system: The biomass material (wood chips, branches, leaves, etc.) is fed into the hopper of the pelletizing machine and mixed with air. Then it changes into pellets through extrusion and drying.

Pelletizing system: The moisture content of the biomass material is less than or equal to 30%. It enters the oven to heat up at a high temperature (600-700℃). During this process, under pressure and vacuum, pellets are formed by breaking off from the original biomass material in the solid state.

Drying system: After being heated up in hot air at a high temperature for about 10 minutes, dried biomass material enters into conveying belt where it cools down naturally through conveying or cooling devices.

.

4. What Materials Can I Use to Make Pellets?

There are three primary materials that you can use to make pellets. These include bone meal, corn gluten meal, and ground-up chicken manure.

Bones are inexpensive and easy to find. They can be used as a source of calcium if they are not too old or broken. To use old bones, you must grind them up before adding them to your mixture.

Corn gluten meal is another good option for making pellets because it gives off a lot of nitrogen when cooked. That makes it an ideal fertilizer for plants that need nitrogen, like tomatoes, lettuce, and vegetables such as Brussels sprouts, broccoli, and cauliflower.

Chicken manure is an excellent source of phosphorus essential for plants’ growth. It also contains nitrogen which helps with leaf production and ripening fruits like tomatoes and peppers, so they do not get wasted before they are ripe enough to eat.

5. How Does A Wood Pellet Machine Work?

The wood pellet machine uses steam power to turn a series of rollers. The rollers are attached to a drum that contains the wood pellets, which are then transferred into another drum. The transfer process is then done in reverse, with the second drum rotating in the opposite direction of the first drum. That results in several passes through the machine until all pellets have been processed.

In addition to processing different types of wood, pellet mills can also be used for other purposes, such as producing paper and cardboard packaging materials.

6. How To Make a Wood Pellet Machine?

Making a wood pellet machine is an essential manufacturing process for producing pellets.

It is a complicated process requiring some special equipment, such as using high-performance machining tools and precise control devices in addition to manual operations.

Manufacturers of wood pellet machines should pay attention to quality control during production to ensure that the final products meet their quality requirements.

The making of a wood pellet machine involves the following steps:

Step 1: The raw material is felled and trimmed at the sawmill, then dried in a kiln to reduce the moisture content to less than 12%.

Step 2: The logs are cut into small pieces, then loaded onto a conveyor belt.

Step 3: On the conveyor belt, they pass through a series of machines that separate the wood into smaller pieces.

Step 4: The small pieces of wood are then fed into a pulverizing machine that breaks down the tree into smaller particles called ‘pulverized wood pellets’ or ‘sawdust’ that can be used as feedstock for other products such as paper manufacturing and furniture making etc.

Step 5: The pulverized wood pellets are collected in an appropriate-sized container for storage or transportation purposes depending on their intended use in manufacturing wood products such as furniture or paper manufacturing.

7. Where To Buy Wood Pellet Machine?

There are many online platforms where you can buy wood pellet machines from China manufacturers.

The following are some of the most popular online platforms for buying wood pellet-making machines from China manufacturers:

- alibaba.com

- made-in-china.com

- dhgate.com

- globalsources.com

- aliexpress.com

- chinabrands.com

- huntersourcing.com -China sourcing agent.

8. How To Choose The Right Pellet Mill?

Purchasing a pellet mill is wise if you want to make your pellets for your wood-burning stove. A pellet mill can save you money and time. However, there are many different pellet mills on the market, so knowing which one to buy can be challenging.

The best way to choose a suitable pellet mill is by looking at some of its features. Some of these include:

Ease of use – This includes how easy it is to set up and use your pellet mill and get used to it if you have never used one before.

Durability – Durability refers to how well the machine will last over time and whether it can withstand wear and tear without breaking down or becoming damaged quickly.

Pellet size: A pellet mill’s primary function is to grind raw materials into pellets. The size of these pellets directly affects the output of your product. A larger pellet will require less processing time, meaning more pellets can be processed per hour and more output in one day.

9. How Do We Choose A Reliable Pellet Machine Manufacturer?

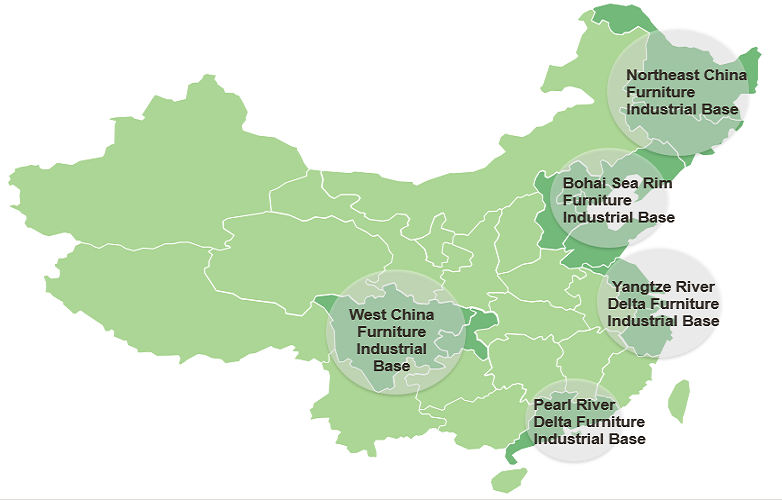

China is a country with fast development which has become a powerful commercial center for the world. The pellet machinery industry has also greatly improved its technology and production capacity.

China is the best place to buy your pellets processing equipment. Many companies manufacture pellet machines. However, if you want to decide on the best option, then it is important to consider some factors before buying a pellet machine. You should know that choosing the right manufacturer can be very important for your business.

Consider the following factors when choosing a reliable pellet machine manufacturer:

• Design

The design of the pellet machine is one of the most important factors you should consider when looking for a reliable machine manufacturer. It would help if you looked for a pellet machine that has a simple design so that it will be easier to use and maintain. You can also choose from different designs depending on your needs and requirements.

• Technology

You should ensure that the pellet machine manufacturer uses the latest technology in its manufacturing process. It is important to consider that newer technology usually costs more than older ones, so it is advisable to research what makes a good pellet machine manufacturer.

• Material

Another thing you should look out for is whether or not their machines are built with environmentally friendly materials. It’s important to make sure that any equipment you choose has been designed in such a way as to be as eco-friendly as possible, so finding out if this is something that they do well is worth looking into.

• Experience

It would help if you also looked for a reliable supplier that is well-established in your industry and has plenty of experience. That means that they have been around for some time, which means they have proven themselves time and time again. If they have achieved success in their industry, then it’s likely that they will be able to deliver great results when it comes to producing high-quality products for your company.

• Competitive Price

Next on our list comes down to pricing. Suppose several suppliers are offering similar products at similar prices. In that case, it might be difficult for customers to buy something new because they will end up comparing prices and deciding which one offers them better value. Therefore, before selecting a supplier, it would be wise to calculate your budget and see if the supplier offers the best deal based on their pricing structure. That will ensure you get the best deal possible without compromising on the quality or performance of their product.

• Quality Control

When it comes to using pellet machines, there is no better place than an industrial facility where experienced people can fix problems quickly and efficiently. The best manufacturers have well-equipped manufacturing facilities that ensure quality control throughout the manufacturing process of their products. That means you will not have to worry about any problems during or after installation because these issues are already taken care of by professionals who already know what they are doing.

• Certification

A good manufacturer should be certified for product quality, production, and delivery. There are different certifications in the industry. The certification process helps you determine whether or not the product is safe and reliable. It also gives you some information on how they manufacture their products. For example, if they have passed all the tests required by their certifications, then it means that they have a high-quality product. That can help you decide whether or not to buy their products.

• Warranty

The warranty with the product you purchase from the manufacturer is also a critical consideration. You should always ensure that there are at least three years of warranty on any piece of equipment before buying it so that if something happens, you can get it replaced without having to pay too much money out of pocket for repairs or replacements.

• After-sales service

The best manufacturers have excellent customer service and will work hard to ensure their customers are satisfied. If a customer has an issue, they should be able to get in touch with the manufacturer directly without any issues. You need to know that you will be able to deal with your issues quickly and efficiently..

10. Wood Pellet Machine FAQ

10.1 How To Start A Biomass Pellets Project?

The first step to starting a biomass pellet business is determining what kind of business you want to establish.

There are several different types of biomass pellet production businesses, including:

• Biomass pellet mills

• Wood chip milling

• Biomass power plants

The second step is to get the right pellet machine. There are many ways to start a biomass pellet project. The most common way is to purchase a pellet machine, but this is not the only option. Depending on your location, you may have access to trees ready for harvest. You can also build your pellet machine or use sawdust or wood chips as fuel.

If you want to start a biomass pellets project, several factors will help determine how much time and money you will spend. For example, if you live in an area with a ready supply of trees or other biomass sources, then building your pellet machine may be more cost-effective than buying one from an outside vendor. This is because it will take less time and money to construct the machine and collect the fuel; however, if you live in an area with limited resources such as land or labor, costs may be higher since these resources must be purchased instead of harvested by hand from nearby trees.

The third step is to find a reliable supplier of high-quality biomass pellets and other biomass products in your area.

Lastly, set up a sales team to promote your business, generate leads and help you grow your business.

10.2 Can I make my own wood pellets?

Yes, you can make your wood pellets. Many people do it and sell the pellets online. The best thing about it is that you can choose the exact amount of pellets you want to make so that you will be able to control the quality of your wood pellets.

10.3 Is it worth it to start manufacturing biomass pellets?

The answer is yes. It is worth it to start manufacturing biomass pellets. It is a very profitable business, and you can make a lot of money.

The reason why it is so profitable is because of the government subsidies that they provide for biomass pellets. The government gives these subsidies to help you get started with your business.

It would help if you did many things before starting your own business, and one of them is to find a good place to manufacture your pellets. This can be done by talking to people who have already started their businesses or looking at their websites or blogs online.

10.4 How to choose a biomass pelletizing machine?

The biomass pelletizing machine is a new type of pelletization machine for biomass. It is mainly used to produce high-quality and energy-saving pellets with a large output and wide application range.

To choose the right biomass pelletizing machine, you need to consider the following aspects:

1. The quality of raw material: Choosing high-quality raw materials such as wood chips or sawdust is necessary. If your local forest has been cut down recently, it is recommended that you buy only fresh wood chips or sawdust.

2. Power consumption: when choosing a biomass pelletizing machine, it is necessary to pay attention to its power consumption during production; the more powerful the machine is, the more energy-saving it will be when using it in production.

3. The transportation length: if you want to transport your products far away, then you should choose a large size of biomass pelletizing machine with a longer transportation distance; if you do not have much space at home or in the factory and want to save money on transportation cost, then small size pelletizing machines are ideal for your needs.

10.5 Do all wood pellets and biomass pellets burn the same?

Yes, they are all the same. The difference is that wood and biomass pellets are made from different materials. The wood pellets are usually made from softwoods like pine or spruce. On the other hand, biomass pellets are more commonly made from hardwoods like oak or maple. Both pellets will burn just fine, but they have different burning characteristics that may affect how you use them in your fireplace.

10.6 Do you know that biomass pellets are also called wood pellets?

Yes, technically, they are both the same thing. The only difference is in their origin and how they are produced. Biomass pellets are made from renewable resources like trees, while wood pellets are made from sawdust and other waste materials. The only thing that differentiates them is their origin and how they’re produced.

11. Why Choose Huntersourcing As Your Wood Pellet Machine Sourcing Agent?

Huntersourcing is a dedicated wood pellet machine sourcing agent who can help you source wood pellet machines from manufacturers in China. Its efficient team of professionals has the expertise and knowledge to assist you with your sourcing requirements from China.

The sourcing agent has established long-term relationships with manufacturers and has access to the best quality wood pellet machines at competitive prices. It has a dedicated team to help you negotiate the price to ensure you get your wood pellet mill at the best price.

Huntersourcing has a large network of distributors in China who can ship directly from their warehouses to your site or port of destination, saving on shipping costs and time delays that may occur if you were to import directly from China yourself. That means you do not have to worry about customs clearance and, shipping & logistics.

The sourcing agent will assist you with all aspects of supply chain management, including sales, finance, accounting, and legal issues related to importing wood pellet machines into your country.

The company has rich experience exporting wood pellet machines and related products to many countries in Europe, America, Asia, and Africa. It does market research and uses the findings to provide consulting services. The company also uses its latest product research findings to recommend the best design for wood pellet machines.

With Huntersourcing as your sourcing agent, your products will only come from a manufacturer that values quality control and allows factory audits to ensure the entire development process adheres to the set standards.

Summary

Huntersourcing is a leading global sourcing agent for wood pellet machinery that works with hundreds of suppliers, manufacturers, and distributors.

We have been delivering over five years of proven experience in supplying high-quality and cost-effective products for our customers. our team of professionals has the expertise and knowledge to assist you with your sourcing requirements from China.

Contact Huntersourcing today to learn more about finding China’s best wood pellet machine.

Related Post

Furniture is a must for an office or a home. It is available at varying price points as Read more

Wood is extensively used in making furniture around the world. Wood can be molded in any shape or Read more

In the current market condition, a major portion of the world's consumption depends on China. The product range Read more

Contact Us Get Free Quote!

* Please kindly fill out the form for inquiry

* we will reply to your inquiry within 24hours