Empower Your Production with a Top-Quality Sewing Machine Supplier

1. What is a Sewing Machine? Types & Applications

2. Industrial vs. Home Sewing Machines: Key Differences

3. How to Choose the Best Sewing Machine

4. Why Source from Chinese Sewing Machine Manufacturers?

5. Top 10 Industrial Sewing Machines for Professional Use

6. Sewing Machine Price Breakdown: Budgeting for Businesses

7. How to Verify a Reliable Sewing Equipment Supplier

8. Selecting the Right Machine: A Step-by-Step Guide

9. FAQs: Where to Sell & Source Sewing Machines

10. Future Trends: Smart Sewing Machines & Sustainability

11. Conclusion

And over the years, the demand and production of sewing machines globally have increased significantly. The industrial sewing machine is the most essential equipment, mostly used for the apparel, textile, and auto industries.

China is the world’s largest sewing machine manufacturer, producing low-cost, good-quality products at par with global standards. Chinese OEM/ODM also offers B2B solutions for brands that want to position themselves in the global market.

This article will explore everything you need to know about sewing machines for industrial and home use. And how to locate good Chinese sewing machine suppliers.

1. What is a Sewing Machine? Types & Applications

A sewing machine is the most important machine widely utilized in the fashion, textile, and automotive sectors to stitch leather, fabrics, and other materials.

Its major components include the needle, presser foot, feed dogs, bobbin, bobbin case, and thread take-up lever to create the stitch.

A sewing machine functions when a threaded needle passes through the cloth and the bobbin thread below it to create an interlock.

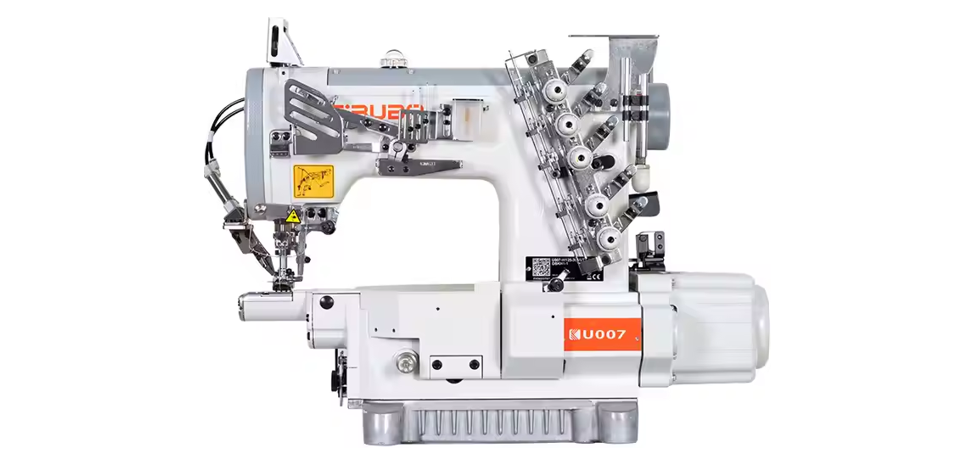

● Industrial sewing machines

Industrial sewing machines are the most commonly used in industry for the production of consumer clothing in large quantities.

They are very highly efficient, fast, and precise in stitching fabrics as well as leather materials. Compared to domestic sewing machines, industrial sewing machines are highly durable—therefore, they can work many hours at a stretch without wear and tear.

Industrial sewing machines, however, are of different kinds based on their application and use. Some of the types of industrial sewing machines are lockstitch, Overlock/Serger, Flatlock/Cover stitch, Button attaching, and Buttonhole industrial sewing machines.

Moreover, most industrial sewing machines are costly because of their quality build and high precision operations.

● Domestic sewing machine

Home sewing machines are mostly used at home for domestic purposes. They are less durable and quality built unlike industrial sewing machines—therefore, they are mostly cheaper.

Household sewing machines are smaller, slower, and less precise than industrial sewing machines.

Home sewing machines, notwithstanding, also perform wonderful work with sewing with multiple functionality.

There are different kinds of home sewing machines, including manual, treadle, mechanical, and electronic home sewing machines.

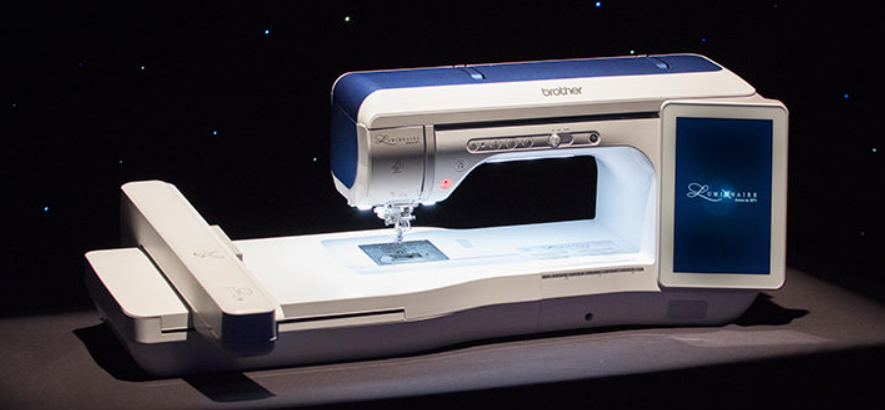

● Specialized sewing machine

Specialized sewing machines are unique sewing machines that carry out unique functions. Specialized sewing machines are computerized sewing machines, embroidery sewing machines, quilting machines, and leather sewing machines. Computerized sewing machines use computerized technologies that enable them to be accessed by mobile phones through USB ports, WiFi, Bluetooth, and NFC.

The computerized and other sophisticated sewing machines are also extremely accurate and adaptable to different types of fabrics.

2. Industrial vs. Home Sewing Machines: Key Differences

Industrial sewing machines are sewing machines designed for industrial use with bulk production in mind.

Home Sewing Machines, on the other hand, are domestic sewing machines. Here are the differences between the industrial and domestic sewing machines.

● Applications and Usage

Industrial sewing machines are suitable for mass sewing in large quantities and industrial bulk production for quick and precise sewing.

They are also employed where there is a need to sew thick fabrics for longer hours. Home Sewing machines are sewing machines for home use and occasional sewing machines. They are less suitable for heavy fabrics.

● Specialization and stitching types

Industrial sewing machines focus on a single stitch type or operation, i.e., blind stitch, overlock, or lockstitch. This is good for greater efficiency, precision, and quality in that particular task.

Domestic or home sewing machines have many in-built stitches, i.e., straight, buttonhole, and zigzag stitches, for versatility. Their versatility allows for efficient general-purpose sewing without heavy-duty sewing.

● Long-lasting

The industrial heavy-duty sewing machines are built with heavy-duty metals and sturdy parts. This makes them last longer and makes them resistant to harsh and extended use without getting damaged.

An industrial sewing machine is meant to serve for decades with good performance if it is well-maintained.

Home sewing machines do not long-lasting when used for heavy-duty activities and for prolonged periods.

The reason is that they are made of thinner material, such as plastic, and can deteriorate over time.

● Speed

In terms of speed, the industrial sewing machine is a more powerful, faster sewing machine than a domestic sewing machine.

It employs a using high-power motors with a high speed of about 5,000 plus stitches per minute. Therefore, they deliver stitching at faster rates with increased industrial output.

The domestic sewing machine is slower compared to industrial sewing machines employed industrially, as they have a less powerful motor.

They tend to sew 1000 stitches or fewer per minute. Hence, they are decent for moderate sewing and home use.

● Ease of Use and Maintenance

Heavy-duty industrial sewing machines require greater capability to operate them since they have very fast speeds and specialized operations.

They often require general repair and maintenance to achieve their maximum output.

Domestic sewing machines or home sewing machines do not require rigorous maintenance since they are easy to clean.

Additionally, most home sewing machines are relatively easy to handle since most of these machines are largely automated.

● Sizes and space requirements

Industrial sewing machines are extremely big, need additional space, and are usually placed on a dedicated table.

Domestic sewing machines, on the other hand, are extremely mobile, light, and can easily be moved from one location to another.

3. How to Choose the Best Sewing Machine

● Material and stitch type

One of the most important factors in choosing the best sewing machine is your working materials.

For instance, when sewing shoes with leather, you may use specialized leather sewing machines.

Mind you, if you are sewing cotton and fabrics, you must have an industrial sewing machine designed for working on fabrics.

Also, the stitches required are another factor to consider when choosing the most appropriate sewing machine.

Buy a sewing machine based on your required stitches, e.g., straight, zigzag, buttonhole, overlock, or blind hem.

● Production Volume

The capacity of production is also something to consider when choosing the perfect sewing machine.

If you require a lot of production capacity, industrial sewing machines are best for accomplishing the task. They are extremely efficient, durable, and can withstand long stitching hours.

For the majority of large apparel industries with high daily production volume, they apply industrial sewing machines for quick turnaround.

Therefore, they accomplish most productions with the best stitching in less time.

● Automation needs

Automation needs are another important thing to consider while choosing the most suitable sewing machine.

Machines come with different levels of automation, varying from manual to semi-automatic to automated.

A Manual sewing machine, unlike automatic ones, usually requires a human to run it in its entirety.

While automated sewing machines usually require less human touch and are capable of stitching more per minute with high accuracy.

● Speed and Power

Speed and power of the sewing machine are crucial factors when selecting the most suitable sewing machine.

Choose a machine that can sew fast without the thread snapping, jamming, or skipping.

You would also prefer the power machine with features to handle thick and robust materials such as canvas, leather, or denim without putting undue pressure on the needle or engine.

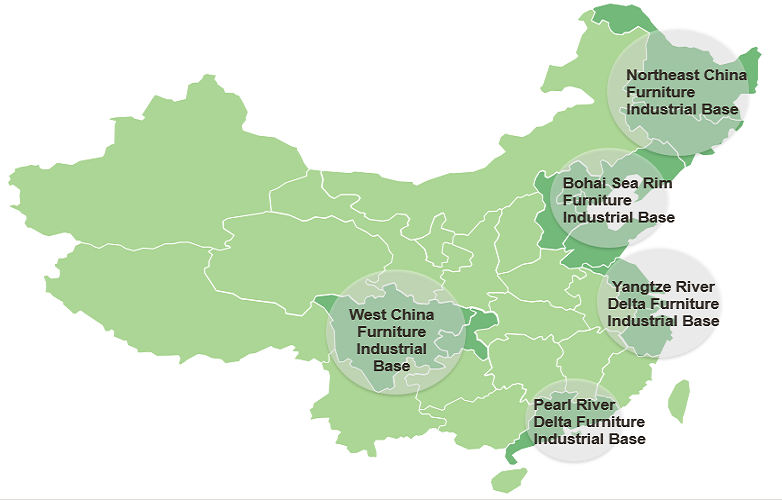

4. Why Source from Chinese Sewing Machine Manufacturers?

● Cost efficiency

One of the main reasons why most brands source sewing machines directly from China is their cost efficiency.

Chinese sewing machines are very affordable compared to those from the West with the same quality.

The cheap labor in China is one of the reasons why Chinese sewing machine manufacturers can provide competitive prices.

This is very helpful to brands that desire to minimize the price of sewing machines without sacrificing quality.

● Advanced Technology

China is also one of the leading countries heavily investing in advanced technology and Artificial Intelligence.

Cutting-edge technology, precision engineering, automated processes, and the latest sewing machine manufacturing techniques are the tools that Chinese sewing machine manufacturers employ.

This makes them one of the leading manufacturers of automated and computerized sewing machines in the world.

Partnering with Chinese sewing machine manufacturers will keep you up to date with the latest happenings in sewing machine automation.

● Scalability and Flexibility

Another benefit of having Chinese sewing machine manufacturers is that they can expand their production if there is more demand as your company grows.

Chinese manufacturers can supply many sewing machines without any decrease in quality.

● Quality Assurance

Those days when Chinese products were labeled as low-quality or inferior goods are behind us. Now, Chinese sewing machine manufacturers are leading producers of high-quality goods meeting international standards.

Most Chinese sewing machine producers are satisfied with international standards like ISO, which guarantee quality

5. Top 10 Industrial Sewing Machines for Professional Use

● Walking Foot Sewing Machine

A walking food sewing machine is a professional sewing machine that is mainly used for sewing heavy layers of thick and slippery fabrics.

A walking foot sewing machine makes use of a special feed dog that fastens to the presser foot bar. This enables the feed dogs on the walking foot to move up and down simultaneously with the lower feed dogs of the sewing machine when it is in operation.

Thereby, holding both layers of cloth in place and moving them simultaneously and at the same rate.

● Single-needle lock stitch sewing machine

A single-needle sewing machine is one of the most popular types of industrial sewing machines available for professional use.

They can work with various thicknesses of fabrics, including canvas and denim. This type of sewing machine has a single needle thread and a bobbin thread for a perfect straight stitch.

● Double-needle lock stitch machine

The double needle lock stitch machine functions similarly to the single needle, only that it has double needles instead of one. They are both used for sewing straight lock stitches.

The two needles function simultaneously by running parallel to each other, thus creating a double stitch. It is mostly used to make double stitching on jeans, shirts, overcoats, and other clothes.

● Chain stitch sewing machine

A chain stitch sewing machine is an industrial sewing machine that creates chain stitches by looping a thread around another thread.

The stitches are stretchable without breaking and can be used for stretch fabrics to securely hold them.

Also, it can be used for hemming the legs of Jean’s trousers to securely hold them in place.

● Overlock/Serger Machine

Overlock/serger machines are mostly used to lock/sew the two edges of sturdy two pieces of fabric.

They usually come equipped with three to five threads, which are loopers fed instead of a bobbin.

There are also two main types, with the basic type sewing basic lockstitch and the other sewing overlock chain stitches.

Overlock/serger machines also come with a cutter that trims the edge of the fabrics simultaneously with the sewing.

They are most employed in finishing the edges of sportswear, fleece fabrics, knits, and more.

● Flatlock/Cover Stitch Machine

The flatlock or cover stitch machine sews cover stitches by interlooping threads (looper threads with those of the needle threads).

It usually comes with two or more needles to achieve different types of stitches.

This type of sewing machine can be used to achieve flat seaming, hemming knit garments, attaching elastics, and pocket facing of jeans.

● Feed of the arm machine

Feed of the arm machine is most commonly used in jeans for lapped seams. It is commonly used to attach the back yoke and the front raise.

The feed of the arm machines is also used for making shirts, back yoke and front raise, and other medium to light-weight fabrics.

● Blind stitch machine

This machine specializes in sewing an invisible stitch that is used for hemming trousers, skirts, and shorts.

It succeeded the age-old practice of blind stitching by hand for commercial mass production lines.

● Button attaching machine

The bottom-attaching sewing machine is used to sew buttons to fabric using lock stitches.

The machine can be programmed to change its settings based on two, four bottom holes by simply adjusting the button clamp and spacing mechanism.

However, more automated versions have an automated button feeding system, which eliminates the need for manual adjustment or placement of buttons.

● Buttonhole Machine

Buttonhole sewing machines are used to create buttonholes on fabrics with lock stitching or chain stitching.

The lock stitch is mainly common because it makes strong stitches, while chain stitches are employed for stretch fabrics.

The buttonhole machines may be programmed to produce a variety of buttonholes and include a knife for cutting through the buttonhole.

6. Sewing Machine Price Breakdown: Budgeting for Businesses

Knowing sewing machine prices is a very important step for your brand to plan and budget for the business.

Prices of various sewing machines differ depending on so many factors. Here are some of the most important factors to keep in mind while budgeting for your next purchase of sewing machines.

● Machine type

The type of machines is an important factor to consider when budgeting for sewing machine costs.

Domestic home sewing machines are some of the cheapest sewing machines, but are limited to use at home or occasional use.

Heavy-duty industrial sewing machines are better options for brands that are into bulk clothing production lines.

For instance, a straight lockstitch industrial heavy-duty sewing machine usually costs $200 to $300 for semi-automatic lock stitches.

A semi-automatic industrial bottom-hole sewing machine, though, can be as high as $800 to $1000.

An automated embroidery sewing machine will cost between $3000 to $5000 directly from China.

● Customization

The level of customization that you need is something else that you should consider when budgeting for your next set of sewing machines.

Especially if you choose an OEM/ODM solution to achieve different levels of customization for your required sewing machines.

For customization, add your logo, company name, and other customizations to make your brand stand out.

You should, however, understand that additional customization comes with higher costs for sewing machines.

● Bulk discounts

One of the most successful ways of reducing the landing cost of Chinese sewing machines is through bulk orders.

Chinese sewing machine manufacturers can provide discounts on bulk orders based on a stipulated MOQ by suppliers.

Similarly, you can also negotiate with them to reduce the price of a sewing machine if you are buying in bulk

7. How to Verify a Reliable Sewing Equipment Supplier

● Check certifications (ISO, CE)

When looking for where to buy sewing machines, you can differentiate a reliable sewing equipment supplier by checking necessary certifications.

Reputable Chinese manufacturers usually hold necessary international certifications to demonstrate good trade practice.

Ask for ISO and CE certification to ascertain quality standards and good trade practice.

● Request samples

Before you make bulk orders, you should ask for a sample so that you can establish the quality of the sewing machine.

A good and credible company would send you samples so that you can learn more about the product.

Ensure you check the quality of the sewing machine, including the speed, efficiency, and build quality.

● Audit factories

A factory audit can help you understand the manufacturer’s level and quality of product.

Most reliable factories usually grant third-party inspections of their factories.

You may contact these third-party inspection bodies for the factory audit, or better still, you may visit the physical location.

● Customer reviews and ratings

Another important factor to consider is customer reviews and product ratings on the online marketplace.

A good product speaks for itself, and many customers are likely to leave reviews for a good product and vice versa.

Check the product review ratings and take time to read reviews of past customers.

8. Selecting the Right Machine: A Step-by-Step Guide

Most people tend to wonder: What is the best sewing machine to buy? Sadly, there is no one-size-fits-all answer to this since the perfect sewing machine depends on many variables.

● What do you need the machine for?

The very first thing you must decide is the purpose the sewing machine is intended to serve, and the type of project you want to accomplish.

For instance, if you need a sewing machine for occasional or general sewing, a domestic sewing machine may be the solution for you.

However, if you are looking at mass production, you should then use the specialized industrial sewing machines.

● Types of stitches

Once you have identified what you need the machine for, you need to list out the kind of stitches that you need for your project.

A straight lockstitch sewing machine is very important for most users going into their first production line.

However, you may need to buy other machines like a serger, a walking foot, cover stitch, buttonhole machines, and so on.

Purchasing high-tech sewing machines will give your clothing line production a sophisticated and elegant look to clients.

● Material thickness

Another thing that you have to consider is your working material thickness. You should use the right sewing machine made for the type of material you are using.

For instance, for leather, use a leather sewing machine specific to sewing leather.

● Consider production volume and automation

Next, volume production, which could determine whether you will need to automate or not.

If what you do is mass production, you may be required to opt fo a computerized sewing machine that is automated.

Such a machine takes less human interference and can output many stitches per minute than other machines.

● Buy from reliable suppliers

After you have chosen what you need in a sewing machine, it is important to buy from a reliable manufacturer.

Having a good connection with a reliable Chinese manufacturer will guarantee you an excellent-quality sewing machine lasting years.

They could also guide to discover the best sewing machine for your needs.

9. FAQs: Where to Sell & Source Sewing Machines

Where to sell and buy sewing machines?

To buy a sewing machine, you need to contact trusted sewing machine suppliers. You can get a trusted sewing manufacturer from the following platforms.

● Alibaba.com

● Made-in-china.com

● Dhgate.com

● Globalsources.com

● Aliexpress.com

● Chinabrands.com

Do sewing machine suppliers from China offer a warranty?

Yes, most Chinese sewing machine manufacturers offer a warranty not least 2 years.

Do Chinese manufacturers offer logistics services?

Yes, most Chinese sewing machine suppliers ship to any part of the world. You will, however, have to pay an extra shipping fee.

How do I buy a quality sewing machine?

While buying from the above marketplace, make sure to buy sewing machines from verified manufacturers. Also, make sure that the manufacturer has a verified badge on the platform before you engage thems

10. Future Trends: Smart Sewing Machines & Sustainability

The next generation of artificial intelligence, automation, and intelligent technology is changing the game in industries.

The new technologies are changing production efficiency, precision stitching, and smart sewing machines in ways never before.

Some of the important future trends that could make sewing machines even better are as below.

● AI-Driven Smart Embroidery

The AI-driven smart embroidery uses artificial intelligence to automate the design process with a couple of prompts.

AI-powered embroidery also senses fabric thickness and type and automatically adjusts stitch settings for the best embroidery result.

In addition, with the use of AI, sewing machines can easily identify and correct errors such as alignment errors, thread breaks, and skipped stitches.

Furthermore, we may like to witness more AI functionalities in sewing machines in the future, such as voice control and more.

● Sustainable and Energy-efficient models

The recent development has witnessed sewing machines that consume much less power than the older models.

This is because they use servo motors are designed to consume less power than clutch motors, hence eliminating wastage and increasing sustainability.

Some manufacturers are using sustainable materials in producing sewing machines..

● Internet of Things (IoT) & Cloud Connectivity

IoT-enabled sewing machines can help manufacturers monitor the health of their machinery by sending performance data to cloud dashboards.

AI analyzes these usage trends to identify impending failures and minimize downtime.

Additionally, manufacturers can add new features and enhance performance through remote software updates for sewing machines.

Conclusion

For businesses, having access to good and reliable sewing machines is a non-negotiable for efficient production.

Partnering with Chinese OEM/ODM sewing machine manufacturers will not only give you affordable sewing machines but also quality and state-of-the-art computerized sewing machines.

Contact us for free factory tours and quotes..

Related Post

Furniture is a must for an office or a home. It is available at varying price points as Read more

Wood is extensively used in making furniture around the world. Wood can be molded in any shape or Read more

In the current market condition, a major portion of the world's consumption depends on China. The product range Read more

Contact Us Get Free Quote!

* Please kindly fill out the form for inquiry

* we will reply to your inquiry within 24hours