Unlock China’s Socket Industry with Expert Sourcing

1. Introduction

1.1 Definition of sockets and their importance in various industries

1.2 Why import sockets from China?

2. Types of sockets

3. Researching potential Socket manufacturers

3.1 Online resources for finding manufacturers

3.2 Trade shows and exhibitions

3.3 Evaluating the Manufacturer’s Capabilities and product quality

3.4 Requesting samples

4. Evaluating Manufacturer Capabilities and Quality Control

4.1 The importance of evaluating a manufacturer’s capabilities and quality control measures

4.2 A checklist of key factors to consider when evaluating manufacturer capabilities and quality control

4.3 Conducting factory visits and quality control inspections

5. Negotiating Pricing and Payment Terms

5.1 Negotiating pricing and payment terms with manufacturers

5.2 Common pricing terms used in the industry

5.3 Discuss best practices for negotiating favorable pricing and payment terms

6. Shipping logistics

6.1 Choosing the right shipping method

6.2 Customs Clearance and Documentation

6.3 Avoiding shipping pitfalls

7. After-sales service

7.1 Ensuring product quality

7.2 Dealing with defects and returns

7.3 After-sales service and support

8. Conclusion

1. Introduction

Finding the best socket manufacturer in China is a daunting task. A good socket manufacturer will have a wide selection of sockets for you, and you will find one that fits your needs.

The problem is that most people need help finding the best socket manufacturer in China. You may have heard of some of the big names in Chinese sockets, but how do you get the best results out of them?

This article will provide all the information you need to find the right socket supplier in China.

1.1 Definition of sockets and their importance in various industries

A socket is a device that allows a person to insert and remove an electrical plug into a receptacle. The term is used for both two-pin plugs and three-pin plugs but may also be used for other plugs.

In some parts of the world, sockets are called jacks. It is because they were initially made from “jacks” similar to the ones used by blacksmiths in the 19th century. These jacks were made from cast iron, which was later replaced with aluminum because it was cheaper.

Sockets are essential in any industry where there is electricity present. They allow for easy connection between electrical equipment and electrical outlets, which can be found in homes and businesses.

1.2 Why import sockets from China?

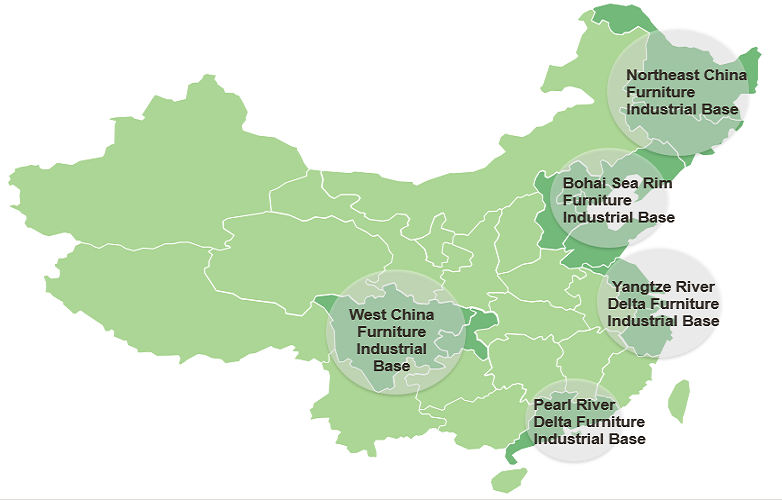

It is no secret that China has been a major player in the global manufacturing sector for years. But with the country’s rising status as a worldwide leader in technology and innovation, it has become an increasingly attractive place for American companies to set up shop.

While there are many benefits of importing sockets from China, here are some of the most compelling benefits:

• Quality is almost guaranteed

The Chinese government has long advocated for quality manufacturing, which is why their standards are so high. That makes it easy to trust that your imported sockets will be made using high-quality materials and craftsmanship.

• Cost

China is known for producing goods at a lower price than many other countries. Importing sockets from China may be a cost-effective way to purchase large ones.

• Variety

China has a wide variety of manufacturers producing different types of sockets, which means you can find a more comprehensive selection of sockets to suit your specific needs by importing them from China.

• Availability

Depending on where you are located, it may be challenging to find specific types of sockets locally. Importing from China can be a way to access a broader range of products that may not be available in your area.

2. Types of sockets?

The number of sockets in the world is growing at a fast pace. The best way to find out if you need one or two sockets is to look at the size of your workspace. If you have a small area, then only one socket will do. If you have a larger area, then two sockets are required.

Sockets come in different sizes and shapes. Depending on your requirements, other sockets have various features and functions. The most common types of sockets are:

• Network sockets

These are used for connecting networking cables to devices, such as computers or routers, and are commonly found in offices or homes. Examples include Ethernet, RJ45, and RJ11 sockets.

• Audio sockets

These are used for connecting audio cables to devices, such as headphones or speakers, and are commonly found on electronic devices like phones or music players. Examples include a 3.5mm audio jack, RCA, TRS, XLR, and TS sockets.

• Video sockets

These are used for connecting video cables to devices, such as TVs or monitors, and are commonly found on electronic devices like laptops, gaming consoles, and media players. Examples include HDMI, VGA, DVI, DisplayPort, and RCA sockets.

• Automotive sockets

These are used in vehicles for connecting power or accessories, such as cigarette lighters or USB chargers. Examples include OBD2, Hella, and lighter sockets.

Other types of sockets include.

2.1 Electrical sockets

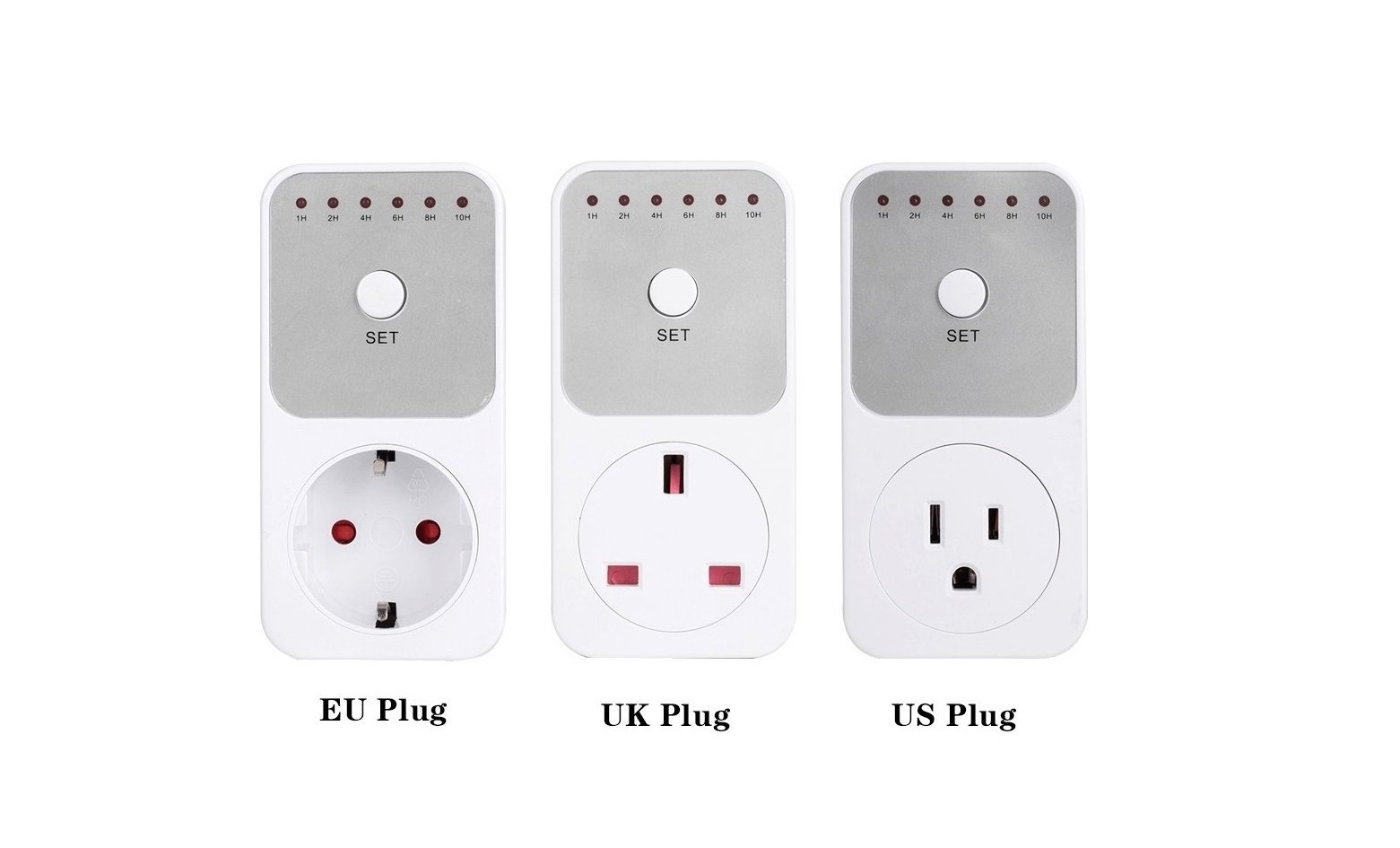

Electrical sockets connect electrical appliances to a power supply, commonly found in homes and buildings. Examples include Type A, B, C, D, E, F, G, H, I, J, K, L, and M sockets..

2.2 Power sockets

A power socket is a device that allows the user to attach electrical appliances such as fans and lights to their electrical system. Power sockets are often found in bathrooms, kitchens, and bedrooms. A power socket is often referred to as an electrical outlet or an electrical receptacle.

Power sockets can be used with either AC or DC. AC (alternating current) power is more commonly used in most countries worldwide because it uses a constant voltage, whereas DC (direct current) power requires more steps to convert from high voltage to low voltage and back again.

2.3 Industrial sockets

Industrial sockets are designed to withstand harsh industrial environments. They are usually made from a combination of plastic, aluminum, and steel. The most common type of industrial socket is the 1/4-20 socket. This socket type is used for applications requiring an extremely tight fit, such as when installing machine parts or wiring inside a vehicle.

2.4 Wall sockets

The wall socket is a single-outlet device that connects one electrical appliance to one electrical circuit. It is called a wall socket because it can be installed in any room or area and is connected to a power source on the same circuit as the appliance itself. For example, if you have an electric kettle and want to plug it into the wall, this socket type would suit you. You can also use them to connect multiple appliances simultaneously to save space or money on electricity bills.

2.5 Plug sockets

A plug socket is a two-outlet electrical device with two separate flat metal blades that fit in a hole in the wall. The plugs are inserted into the sockets and then into an electric source.

A plug socket connects a power source to up to two appliances. It may also be used with a surge protector to protect electronic equipment from power surges or spikes.

2.6 USB sockets

USB sockets have a small hole at the end of the socket, and some USB cables have a plug that fits into this hole.

USB sockets are also called “mini-B” because they are smaller than the standard “A” size. Mini-B sockets can be used with “A” and “B” size plugs, but they do not work with anything else. The only other way to connect a device to a mini-B socket is by using an adapter cable.

2.7 Switch sockets

A switch socket is a type of electrical outlet that has two or more receptacles in it. It allows you to power multiple devices simultaneously and is also a great way to add switches for lights, fans, and other appliances.

2.8 Waterproof sockets

Waterproof sockets are designed to be used in harsh environments and resist water, salt, dust, and other aggressive elements. They are ideal for temporary applications where the socket is exposed to water or dust.

2.9 Socket outlets

Socket outlets are available in every home and office. They connect electrical appliances such as lamps, fans, televisions, and other electrical equipment. These sockets have different voltages, and they can be used to connect any appliance. It is a plug-in type of outlet that has an adapter with it. The adapter has a socket outlet, which converts the voltage from one type to another.

2.10 Extension sockets

Extension sockets are a vital part of a home’s electrical system. Extension sockets allow you to plug additional electrical devices, such as power strips or extension cords, into one socket extension.

3. Researching potential Socket manufacturers

When importing from China, it is crucial to know the socket manufacturer’s quality and ability to deliver on time.

If you are planning on importing from China, it is crucial to research potential socket manufacturers before you place an order. That will ensure that you are placing an order with a reliable company that can deliver on time and in good condition.

The first thing that you will want to do when researching potential socket manufacturers is to look at their customer feedback. It can be found on review sites like Trustpilot and Trustpilot for Electrical & Engineering Goods. You should also look at their social media presence and see if there are any negative comments about their product or service. If there are any, it would be wise not to place an order with them.

3.1 Online resources for finding manufacturers

The first step in the importation process is to research potential socket manufacturers. That is done by checking with other suppliers and distributors, as well as using online sources such as

1. alibaba.com

2. made-in-china.com

3. dhgate.com

4. globalsources.com

5. aliexpress.com

6. chinabrands.com

7. huntersourcing.com -China sourcing agent.

3.2 Trade shows and exhibitions

The manufacturing capabilities of the control panel manufacturer are very important. The more complex your system, the more complex your control panel needs to be. You should always go for a manufacturer who has been in this business for a long time and has enough experience to handle your specific needs. You can also check online reviews about their manufacturing capabilities to decide whether they are capable enough to fulfill your needs.

3.3 Evaluating Manufacturer’s Capabilities and product quality

When evaluating the manufacturer, looking at their capabilities and product quality is essential. The best manufacturers will have a wide variety of products that they can offer to you. They should also be able to guarantee the quality of their products.

If you are looking for a specific product type, ensure the manufacturer has one available or can make it for you. That will ensure you get exactly what you need when importing from China.

3.4 Requesting samples

When you find the manufacturer, you must request samples of their sockets and other products. If you want to ensure the socket will fit your product, ask for samples in the exact sizes. You can also request video demonstrations of their work on a specific product model.

4. Evaluating Manufacturer Capabilities and Quality Control

In the process of buying sockets from China, there are some things that you must consider before choosing a product. One of them is the capability of the manufacturer to produce high-quality products.

It is also vital to ensure that the manufacturer has a good reputation and is well known in the market. It will help ensure you get quality products at an affordable price.

You can learn more about a manufacturer’s capabilities through their website. You can also contact several companies and ask them about their capabilities and quality control when producing sockets for sale in China. Also, ask them about their experience with other customers who purchased sockets

4.1 The importance of evaluating a manufacturer’s capabilities and quality control measures

Evaluating a manufacturer’s capabilities and quality control measures is crucial when importing sockets from China because it can help ensure that you receive products that meet your requirements and are of high quality. Here are some reasons why this is important:

• Product Quality

Poor sockets can be dangerous and cause electrical fires, electrical shocks, or damage to equipment. By evaluating a manufacturer’s quality control measures, you can ensure their products are safe and reliable.

• Consistency

A manufacturer’s capabilities and quality control measures can affect the consistency of its products. If a manufacturer has weak quality control measures or limited abilities, there may be variations in the quality of their products, which can cause problems with compatibility or reliability.

• Reputation

A manufacturer’s reputation can be an indicator of the quality of its products. By researching a manufacturer’s reputation and reading reviews from other customers, you can get an idea of their track record and the quality of their products.

• Compliance

Importing sockets from China requires compliance with safety standards and regulations in your country. By evaluating a manufacturer’s capabilities and quality control measures, you can ensure that their products meet the necessary safety standards and regulations.

• Cost-effectiveness

While choosing a manufacturer based solely on price may be tempting, evaluating their capabilities and quality control measures can help you determine if the cost savings are worth the risk. Poor-quality products can result in costly returns or repairs, which can offset any savings from choosing a cheaper manufacturer.

4.2 A checklist of key factors to consider when evaluating manufacturer capabilities and quality control

When you import sockets from China, it is essential to look at the following key factors and evaluate them before placing an order:

• Production capacity

The production capacity of a manufacturer is the most crucial factor to consider when evaluating its capabilities and quality control. If a manufacturer claims to be able to supply thousands of sockets per day, then you can be sure that they can do so.

• Equipment

The equipment the manufacturer uses is an essential factor to consider when evaluating the quality of the socket. The equipment should be in good condition and well-maintained. In addition, the efficiency of the equipment should meet the needs of customers.

• Certifications

Check if the manufacturer has relevant certifications such as ISO 9001 or UL to ensure their quality control processes are up to par.

It is crucial to ensure the manufacturer has a well-defined quality control process to ensure the sockets meet your quality requirements. This process should include testing the product for functionality, durability, and safety before and after production.

The manufacturer should have a strong quality control team to monitor the production process and inspect the product before shipment to ensure that the product is free from any defects or errors.

Verifying that the manufacturer adheres to international quality standards is essential to ensure consistent product quality.

4.3 Conducting factory visits and quality control inspections

Quality control inspections and factory visits are the best ways to evaluate a manufacturer’s capabilities. These activities help determine where to focus your time, money, and resources.

Factory visits allow face-to-face communication with key stakeholders in the manufacturing process. That sets you apart from other companies conducting more superficial assessments of the company based on their website or brochure material.

These two types of assessments are critical because they allow you to see how a product is made, what goes into it, and how it is packaged for shipping purposes. They can also give insight into how the finished product will perform in an application environment.

5. Negotiating Pricing and Payment Terms

When you import sockets from China, you want to ensure you get a good deal. Negotiating pricing and payment terms with manufacturers when importing sockets from China is like negotiating with them when importing other products.

5.1 Negotiating pricing and payment terms with manufacturers

The first step in negotiating with a manufacturer is determining the price you will pay for their product. The best way to do this is to visit the manufacturer’s website to see their most recent prices. You can also contact them directly by phone or email.

Once you have determined the price, it’s time to meet with the manufacturer. Before meeting with them, ensure everything has been arranged and confirmed, including all costs of getting your products from China to your shop.

5.2 Common pricing terms used in the industry

The following are some of the most common pricing terms Chinese socket manufacturers use when selling to overseas buyers.

• FOB (Factory Outlet): FOB is the most common price for Chinese manufacturers, meaning the product will be shipped from their factory to your destination, saving shipping costs.

• CIF (Cost, Insurance, and Freight): CIF is used when purchasing a product from its factory to your country. It indicates that you will pay for all costs of transporting the item, including insurance.

• DDP (Delivery Duty Paid): DDP is added to your purchase price after paying import taxes.

5.3 Discuss best practices for negotiating favorable pricing and payment terms

Several best practices can help you to negotiate favorable pricing and payment terms:

Do your research: Before entering into any negotiations, thoroughly research the Chinese manufacturers you are interested in working with. Look for reviews and references from other businesses that have imported from them, and check their reputation with the Chinese government and industry associations.

• Understand the market

Knowing the current market conditions for sockets can give you a better idea of what pricing and payment terms to expect. Keep up to date with current events and news related to the industry, and track pricing trends over time.

• Build a relationship

A strong relationship with the manufacturer can help you negotiate better pricing and payment terms. Regular communication and visits to the manufacturer’s facility can help you build trust and rapport, making it more likely they will be willing to work with you.

• Be clear about your needs

Communicate your needs clearly with the manufacturer, including your desired pricing and payment terms. Be open to negotiation, but be firm about what you are willing to pay and the required terms.

• Consider bulk orders

Ordering larger quantities can often lead to lower prices and more favorable payment terms. However, be sure to calculate the total cost of the order, including shipping and import fees, to ensure it is still cost-effective.

6. Shipping logistics

An essential step in shipping logistics when importing sockets from China is finding a reliable company to help you import your product. Always look for a company that has good reviews and has been in business for a while.

6.1 Choosing the right shipping method

The most important thing when importing sockets from China is to choose a suitable shipping method.

There are many shipping methods, and it takes work to choose the right one. If you want to get a good deal on your imports, you should always check all possible shipping methods at once and compare them. It will help you save money and time because one method may be cheaper than another, but it may be slower, so you need to balance these two things out before making your final decision.

The following are some of the most common methods used by importers:

• FedEx

This is one of the most popular shipping methods for Chinese sockets. It is an international courier company that offers some of the lowest rates for sending packages overseas (even free). However, this option may only suit some because it requires trust in their service quality.

• DHL

This is another popular shipping method for Chinese sockets. It offers various services such as digital tracking, customs clearance, insurance, and delivery confirmation. However, it also has higher rates than FEDEX.

• UPS/DPD/TNT

These are also popular shipping methods for Chinese sockets but have lower rates than FedEx or DHL.

6.2 Customs Clearance and Documentation

When importing sockets from China, it is vital to be aware of the customs regulations and restrictions, as they can affect the cost and time to deliver your order.

The first thing you need to know is what types of goods are subject to duty, which is calculated on the value of the goods. For example, if you are importing a socket set valued at $100 and your order weighs approximately 2kg, your total import duty will be $20.

As well as the duty rate, there are restrictions on what type of goods can be imported into Australia via air freight. Some items may only enter using sea freight, meaning you must pay extra for delivery.

6.3 Avoiding shipping pitfalls

When importing sockets from China, it’s essential to be aware of the pitfalls that can occur during shipping. Here are some tips to help you avoid shipping pitfalls when importing sockets from China:

• Understand the shipping terms

Make sure you understand the shipping terms before placing your order. Some suppliers may offer free shipping, but the cost is often included in the product price. Other suppliers may offer low prices but charge high shipping fees, so compare prices and shipping costs carefully.

• Get a detailed quote

Before placing your order, ask for an exact quote that includes all costs, including the product price, shipping fees, customs duties, and taxes. Ensure you understand all the costs and factor them into your budget.

• Choose a reliable shipping method

Choose a reliable shipping method that offers tracking information. That will help you keep track of your shipment and ensure it arrives on time.

• Understand customs requirements

Ensure you understand the customs requirements for importing sockets into your country. You may need to obtain a license or permit, pay customs duties and taxes, and comply with specific regulations..

7. After-sales service

After-sales service is something that you should consider when importing sockets from China. The best supplier will provide you with the best after-sales and follow-up services. The after-sales team will solve your problem quickly and efficiently, so you can get back to work as soon as possible.

After-sales service includes the following:

• Warranty on all products sold by our company;

• Free technical support for three years after the purchase date;

• Free replacement or refund if our products cause any problem;

• Fast delivery (usually within 1-5 working days);

• Cost-effective shipping fee for large orders;

7.1 Ensuring product quality

Quality is one of the many factors that go into choosing a socket manufacturer. One of the most important factors to consider is the quality of their products. A good socket manufacturer will always ensure that their products are made from high-quality materials and components, so you can be sure that the sockets will last for years.

Many things can affect the quality of your tools and sockets, including:

• The materials used to manufacture the parts

• The manufacturing process employed by the manufacturer

• The quality control procedures in place (or not) at each stage of production

7.2 Dealing with defects and returns

Dealing with defects and returns when importing a socket from China can be challenging, but it’s an essential aspect of doing business with overseas suppliers. Here are some steps you can take to manage defects and returns effectively:

• Quality control

Before the shipment leaves the factory in China, you should have a third-party quality control inspection to ensure the product meets the required quality standards. This inspection should include a review of the product’s specifications, labeling, packaging, and performance.

• Negotiate returns and refunds

If the defect is significant, you may need to negotiate a product return or a refund with the supplier. Ensure you clearly understand the supplier’s return and refund policies before placing your order. You should also consider the cost of returning the product to China, as it can be expensive.

• Document everything

Keep a detailed record of all communication with the supplier, including emails and phone calls. That will be useful if you must escalate the issue to a higher authority or take legal action.

7.3 After-sales service and support

After-sales service and support refer directly to the level of services that a socket manufacturer provides their customers after purchasing their product from them. It includes technical support, warranty coverage, and repair services.

8. Conclusion

Finding good socket manufacturers in China may seem like an overwhelming and challenging task, but it doesn’t need to be. You can find a reliable supplier within days or even hours with the proper knowledge.

We have highlighted all the tips for successfully importing sockets from China. Through this article, we have highlighted the future outlook for importing sockets from China for your understanding and to make your search easier.

Contact us to get a free quote now!

Related Post

Furniture is a must for an office or a home. It is available at varying price points as Read more

Wood is extensively used in making furniture around the world. Wood can be molded in any shape or Read more

In the current market condition, a major portion of the world's consumption depends on China. The product range Read more

Contact Us Get Free Quote!

* Please kindly fill out the form for inquiry

* we will reply to your inquiry within 24hours