Unlocking Success: Your Guide to Cosmetic Bottle Suppliers in China

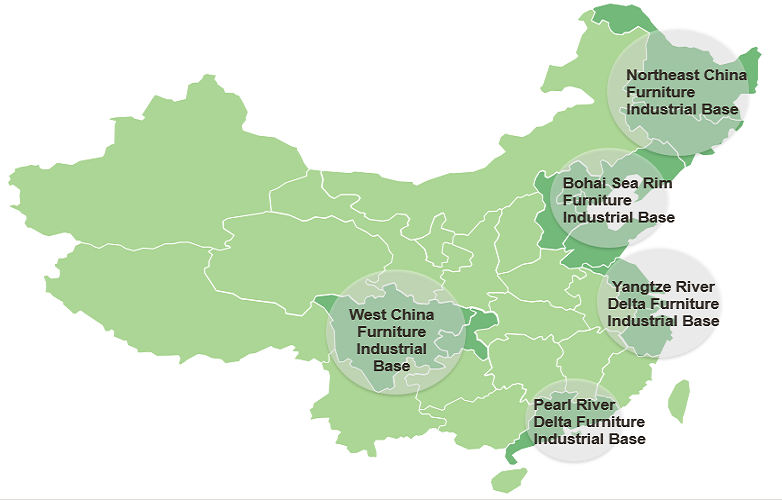

China has cemented its position as the number one producer of cosmetic packaging globally, from slick pump bottles to colorful lip gloss vessels.

As cosmetic bottle manufacturers invest heavily in advanced equipment and capacity scaling, importers benefit through access to affordable, quality options.

This piece will explore top Chinese suppliers, popular materials, key export markets, and considerations when sourcing bottles destined for prime retail displays.

1. Why Import Cosmetic Bottles From China?

2. What Are the Types Of Cosmetic Bottles?

3. What Should Buyers Consider When Choosing A Chinese Cosmetic Bottle Supplier?

4. Where To Buy Cosmetic Bottles

5. How to Choose a Cosmetic Bottle Manufacturer

6. How to Customize Cosmetic Bottles from China

7. What are the quality standards and certifications for cosmetic bottles?

8. Top 10 cosmetic bottle manufacturers in China

8.1 Zhejiang Ukpack Packaging

8.2 Zhejiang Fuquan Plastic Industry

8.3 Yuyao Longzhuang Plastic

8.4 Guangzhou Zimay Plastic

8.5 Shaoxing Yicai Plastics

8.6 Hangzhou Yuhang Zhenhua Daily Chemical Glass

8.7 Xiamen Tiumsen Cosmetics

8.8 Zhejiang Cosme Industry

8.9 Guangzhou Panyue Packing

8.10 Guangzhou Jiaxing Glass Products

9. Why Choose Huntersourcing As Your Cosmetic Bottle China Sourcing Agent?

Conclusion

Get The Experts on the Job

1. Why Import Cosmetic Bottles From China?

With an integrated supply chain spanning materials procurement to turnkey manufacturing, Chinese cosmetic bottle factories provide a one-stop solution for cosmetics packaging needs from mass markets to luxury niches.

Their infrastructure produces plastic bottles worldwide through efficient specialization. State subsidies for export sectors enable very competitive pricing as well.

As cosmetic consumption surges thanks to beauty influencer culture and self-care trends, Chinese suppliers continue expanding operations to serve booming demand, especially across Asian, European, and North American markets.

Luxury brands increasingly shift production from France and Italy to China for crystal-clear acrylic bottles and metallic capped vessels. China now leads finished packaging capacity globally.

With expertise in fabricating glass, plastic, and metal components at scale, Chinese manufacturers offer brands versatile, affordable cosmetic bottles catering from skin serums to shower gels continue gaining market share for quality and value.

Sourcing bottles locally simplifies logistics for China-based cosmetics marketers. China is also the second-largest consumer market for cosmetic products.

Additional key reasons why China dominates cosmetic bottle production include:

● Cost savings – Average pricing is 30-50% below Europe and North America for identical quality and components

● Production agility & capacity – A skilled workforce and abundant facilities enable fast sampling and enormous-scale orders.

● Range of materials – Factories adeptly handle plastic, glass, aluminum, and acrylic materials, along with prints, coatings, and decorations

● Vertical integration – Many suppliers oversee the entire value chain, from mold making and manufacturing to branded finishing.

● Export convenience – China’s vast logistics networks offer consolidated shipping at low rates able to reach any global destination.

2. What Are the Types Of Cosmetic Bottles?

Chinese cosmetic bottle suppliers manufacture a vast range of packaging tailored to beauty product formulas and functions. Selecting the optimal vessel depends on attributes like dispensing needs, aesthetics, production methods, and cost thresholds.

2.1 Plastic Cosmetic Bottles

The most ubiquitous category, plastic bottles offer durability, variety, and low per-unit cost through high-volume production. Advanced injection blow molding and extrusion processes craft HDPE and PET resin into diverse shapes with multiple decorative finishings that heighten perceived value.

Smooth, glossy finishes emulate glass for mass-market moisturizers and creams. Metallization through vacuum deposition or ion sputtering adds a sophisticated style worthy of premium shelf placement. Further decorated enhancements like UV coating, spray printing, and labeling increase differentiation in crowded markets.

2.2 Dispenser Variants

Pumps and spray heads provide controlled, hygienic dispensing. Snap-on pump mechanisms with lockable or child-resistant actuators allow convenient, one-handed use for shampoos or conditioners. Fine mist atomizers suit toner, floral water, and setting sprays needing a delicate application.

Lotion pumps often integrate flow restrictors and intake tubes reaching the bottle base to optimize output control and total evacuation. Cover orifices during production help avoid formula contamination.

2.3 Style Types

Rounded bottles with flat or contoured profiles and short necks hold most lotions and creams, especially for body care. Angled shoulders on certain designs assist in handling ergonomics.

Long tapered nozzle bottles suit facial serums, oils, and gel emulsions. Jars and wide-mouth tub styles provide broad openings, making scooping thick cream products convenient and hygienic.

Many brands also leverage fully custom asymmetric shapes for further differentiation.

2.4 Glass Cosmetic Bottles

For luxury essence oils and high-end skin care preparations, glass bottles and jars add a premium aesthetic. Materials like borosilicate glass provide resilience to endure frequent use.

Decorating through screen printing, spraying, or metallization further elevates appeal.

2.5 Aluminum Bottles

Lightweight aluminum bottles finished with coatings appeal for eco-friendly branding, especially recycled aluminum.

The non-porous metal prevents contamination. Bold shapes and metallic sheens align with aspirational positioning.

2.6 Acrylic Bottles

Acrylic offers an optical clarity that glass cannot achieve. Streaming fluid visibility enhances beauty formulation mystique. Acrylic also permits more shaping flexibility tailored to brand identities, from diamond facets to ergonomic curves.

With vast production capabilities, leading Chinese cosmetic bottle suppliers provide brand packaging that captivates consumers while showcasing product benefits. Selecting options purposefully allows differentiation and shelf appeal breakthroughs.

3. What Should Buyers Consider When Choosing A Chinese Cosmetic Bottle Supplier?

Selecting reputable Chinese cosmetic bottle manufacturers as long-term partners involves evaluating several aspects to find suppliers meeting quality, capacity, consistency, and service expectations.

3.1 Range Of Offerings

Catalog variety indicates production capabilities. Need simple cylindrical bottles or multi-part vessels with pumps, caps, and decorative accents?

Top suppliers offer thousands of stock options covering prevailing volumes yet customized for niche orders.

Examine range depth, including shapes, nozzle styles, lid types, decoration methods, etc.

3.2 Vertically Integrated Production

Optimal partners control materials sourcing, mold fabrication, manufacturing, labeling, filling, and final packaging in-house for agility.

Vertically integrated processes prevent delays and enable quality assurance oversight exiting the factory floor. Ask about operational scope.

3.3 Molded & Assembled Components

Whether requiring existing designs replicated or completely custom bottles, understanding production methods matters.

Suppliers should describe molding types like injection, blow, compression, extrusion, etc. based on selected materials like PET, PP, acrylic, and glass.

Expect precision custom mold making for uniqueness with rapid sampling. Assembly conditions should meet air quality, ESD, and contamination protocols.

3.4 Secondary Decorating Expertise

Beyond basic bottles, decorative enhancements increase perceived value. Probe surface treatment offerings like coating, metallization, printing, etching, frosting, and ablation to match packaging with formula positioning.

What finishing media, patterns, textures, and colors are supported? How customizable? What lead times? Quality hinges on decorating mastery.

3.5 Certified Standards Compliance

Reputable players admit 3rd party oversight verifying proper operating conditions for legal compliance and export readiness.

Look for updated ISO 22716, ISO 15378, and ISO 9001 conformance, plus FDA/CFDA registration showing adherence to quality system regulations for cosmetics goods production control.

GMP-audited facilities ensure high consistency and attention to specifications.

3.6 R&D Innovation Culture

Truly customer-focused partners continuously enhance techniques and services. Recent upgrades to offerings indicate dedication.

Whether creating novel decorative textures through laser ablation or streamlining custom sampling turnaround, suppliers should evidence technological progress benefits via documented improvements.

R&D roadmaps sharing future bottle materials research provide confidence as well as a shared vision.

Cosmetic bottle buyers must dig deeper during sourcing to verify world-class manufacturing standards alignment beyond browsing Alibaba listings alone.

Production scale capabilities cannot compromise consistency, decorating finesse, or service responsiveness expectations modern brands rightfully seek.

4. Where To Buy Cosmetic Bottles

Importers have two primary channels for accessing Chinese-manufactured cosmetic bottles – visiting trading centers to view mass inventory onsite or purchasing directly online through manufacturer e-commerce portals.

Both options connect international buyers with the myriad factories fulfilling global beauty packaging demand.

4.1 China Cosmetic Bottle Wholesale Market

Sprawling wholesale markets within major Chinese export hubs provide visitors with a vast centralized selection of packaging across thousands of cosmetics vendors.

The Yiwu China Commodities City spans over 4 million square feet with 70,000 booths selling every consumer product imaginable. Numerous aisles feature cosmetic bottles in all sizes and configurations.

As the world’s largest wholesale hub, Yiwu attracted over 2 million international buyers in 2021 purchasing low MOQs.

Guangzhou hosts the Canton Fair complex and the Cosmetics & Home World display center, where 1,300+ companies showcase packaging.

The adjacent Pazhou complex holds global sourcing fairs. Guangzhou appeals for buying agents arranging export orders directly from adjacent manufacturing zones.

4.2 China Cosmetic Bottle B2B Websites

Alibaba headlines familiar B2B e-commerce venues where China-based packaging suppliers advertise product inventory for direct online purchase.

Importers can order bulk quantities of bottles from factories 24/7 via credit card, Paypal, or wire transfer payment.

MOQ thresholds range from a few hundred units for testing to high volume 20,000+ piece pricing. English-fluent sales teams readily assist global customers.

Made-In-China, GlobalSources, and DHGate operate similar vast searchable databases of available plastic bottles, glass jars, lipstick tubes, quads, and other packaging stock sourced directly from Chinese plants.

Detailed cosmetic bottle listings provide dimensions specs, pricing matrices based on quantity thresholds, material information, technical drawings, production lead times, and views of component mold options for customization.

B2B platforms like Alibaba seamlessly connect international buyers and manufacturers through digital storefronts and communication systems designed for cross-border procurement.

Product discovery tools assist search filtering by specifications while built-in quoting and order tracking remove hassles when importing directly from suppliers.

Language translation assistance further aids the buying processes for smooth transactions via website marketplace flows.

5. How to Choose a Cosmetic Bottle Manufacturer

Selecting the optimal cosmetic bottle partner as a long-term supply chain asset requires strategic analysis when sourcing packaging beyond Alibaba listings alone.

Quality, consistency, and communication directly impact the product experience, so it’s crucial to ask probing questions before committing to a partnership.

5.1 Catalog Breadth

To gain a comprehensive understanding of a prospective factory’s capabilities, request full catalogs indicating their production range.

Investigate the mastery demonstrated in different sizes, shapes, lid types, decoration methods, and ancillary parts. Top suppliers boast thousands of molded configurations and component pairings, covering various formulas.

Additionally, inquire about customization options and assess the speed of sampling and changeover times when switching between stock molds.

Expanding your inquiry to include specialized packaging needs ensures that the supplier can accommodate unique requests, such as eco-friendly materials or innovative design elements.

This thorough examination helps align the manufacturer’s offerings with your brand’s vision for cosmetic products.

5.2 Vertical Integration

Optimal partners exert control over the entire value sequence, from materials procurement and proprietary mold making to rapid manufacturing, decorative finishing, sterile labeling, precision filling, and final kitting.

It’s crucial to ask explicitly about the operational scope, ensuring a seamless process from start to finish.

Vertically integrated processes prevent delays and enable stringent quality assurance oversight from raw resins until packed orders ship.

By delving into each stage of the manufacturing process, inquire about their sustainability practices and how they manage waste.

A commitment to environmentally conscious operations aligns with contemporary consumer values and may enhance the appeal of your cosmetic brand.

5.3 Equipment Automation

Sophisticated programmable machinery, such as high-output injection molders, multi-axis laser etching decorating stations, and in-line leak detection devices, enhances reliability through advanced sensing capabilities.

These stringent process control protocols and precision repeatability are impossible manually.

When evaluating potential suppliers, ask explicitly about recent tech investments and how knowledge is shared between engineering teams.

Furthermore, inquire about the flexibility of their automated systems to adapt to evolving industry standards and emerging trends.

A supplier with a proactive approach to technological advancements ensures that your cosmetic packaging remains cutting-edge.

5.4 Decorating Specialization

Beyond basic bottles, enhanced techniques like spray coating, artistic painting, vacuum metallization, frosting, and pattern etching drastically increase perceived value when done skillfully by masters.

Probe their specific media formats supported, pattern libraries, advanced color matching services, and rapid changeover agility. Finishing expertise makes plain components shine brilliantly.

In addition to these inquiries, explore their commitment to social responsibility in sourcing materials and supporting local communities.

Transparency in ethical practices can enhance the overall image of your cosmetic brand and appeal to conscientious consumers.

6. How to Customize Cosmetic Bottles from China

Seeking fully bespoke packaging directly tailored to product branding? By collaborating with Chinese original equipment manufacturer (OEM) cosmetic bottle suppliers, custom creations transform imagination into physical reality through precision manufacturing mastery.

6.1 Define Objectives

Begin by outlining packaging goals aligned to formulas and positioning.

Consider target demographics, dispensing, sustainability aims, shelf differentiation, purchase drivers, and usability feedback.

Establish ideal textures, sizes, decoration styles, and features suiting brand ethos early. Collect inspiration images.

6.2 Sketch Concepts

Render basic shape ideas either manually or using 3D design software. Simple cylinder packs often serve commoditized products, so explore bolder facets and ergonomic angles.

Decide on openings, fasteners, decorative cutouts, or gradient effects.

Welcome creativity before feasibility analysis.

6.3 Request 3D Modeling

Suppliers then engineer concepts digitally while suggesting tweaks based on material behavior and production methods.

Multi-axis capabilities today enable incredibly intricate forms once impossible or price-prohibitive to manufacture at scale.

Review models virtually through rendering software visualization.

6.4 Review Physical Samples

Fine-tune technical specs in subsequent rounds with actual samples in hand. Samples bring life essential for evaluating a sense of luxury while checking part tolerances and decor alignment.

Request different material types like PET plastic versus glass. Finalize details iteratively until a gleaming manifestation delivers your vision.

6.5 Audit Tooling

When ready to proceed for production tooling fabrication, visit facilities to inspect CNC machining of hardened steel molds cut based on perfected technical diagrams.

Verify surface precision alignment needing consistency for defect-free output able to sustain high-speed manufacturing strains over thousands of cycles.

6.6 Oversee Manufacturing

During pilot runs and mass production, perform random inspections through all process points from molded components getting sprayed, etched, metalized, and cleaned to final assembly with pumps, sprayers, and caps ensuring faultless performance.

Catch any deviations early before full critical lot completion.

Collaborating with versatile Chinese factories liberates brands to launch uniquely differentiating packaging that takes core products to new heights through enhanced tactility and visual appeal, critical on crowded shelves.

7. What are the quality standards and certifications for cosmetic bottles?

Consistency and safety remain vital for trouble-free global distribution.

Trusted Chinese cosmetic bottle manufacturers implement multiple protocols and secure key credentials affirming capabilities.

7.1 Rigorous Testing

All incoming raw materials undergo laboratory verification, which checks composition purity, durability thresholds, and the absence of hazardous substances through chromatographic methods meeting CNAS standards.

Frequent process testing then ensures critical production indicators fall within very tight parametric ranges over entire manufacturing runs using sensors and test result analytics preventing deviation.

Finished products undergo final functional evaluations, assuring uniformity across aspects like spray rate, dose delivery, leakage, and package integrity throughout the expected shelf life. No significant variation is allowed in samples before customer shipments are approved.

7.2 International Standards Certification

To legally export worldwide, leading cosmetic packaging producers comply with ISO 15378, which outlines risk-based GMP requirements, including staff training, traceability practices, contamination control, inspection rigor, and change management principles, when altering any materials or techniques that could impact end products.

Updated ISO 9001 registrations also affirm proper quality frameworks centering customer needs, while ISO 14001 demonstrates environmental commitments through sustainable material preferences and waste minimizations that appeal to eco-conscious brands.

7.3 Supplier Audits

When selecting new manufacturing partners, reputable brands send cross-functional teams to audit production facilities in person, even if certificates seem in order on paper.

Walking assembly lines provides inner glimpses of true process rigor versus doctored presentations. Testing labs and worker skill demonstrations prove indispensable.

7.4 Secure Trade Compliance

Virtually all Chinese export factories pursue business licenses and complete stringent registration procedures to sell overseas compliantly.

Securing Certificates of Origin, export customs clearance and legal outside sale rights for protected products prevent headaches.

7.5 Packaging Validation

Before running mass production, contracted factories perform stability testing through accelerated aging on all packaging components touching formulations including pumps, interior coatings, and sealing liners.

Ensuring no ingredient interactions or migrations provides security.

8. Top 10 cosmetic bottle manufacturers in China

China hosts over 200 thousand enterprises engaged in packaging production, serving industries from ecommerce to cosmetics.

Highly innovative manufacturers continuously raise benchmarks for speed, customization, and quality. We showcase leaders setting global precedents:

8.1 Zhejiang Ukpack Packaging

As premier plastic bottle manufacturers producing 300 million units annually through 13 fully automated assembly lines.

Zhejiang Ukpack Print strives to lead sustainable transformation, evidenced by its use of sugarcane derivatives and biodegradable PP materials converted through expert precision molding into recyclable smooth-sided singular bottle forms befitting body washes.

8.2 Zhejiang Fuquan Plastic Industry

Operating large-scale workshops adept at molding caps, pumps, and specialist plastic packaging, Zhejiang Fuquan Plastic Industry assists international cosmetic brands in sourcing components matching formula viscosities and skincare needs.

They also provide leak-resistant dispensing solutions like fine mist atomizers and patented drip-free lotion pumps for aging care creams needing reliable output control.

8.3 Yuyao Longzhuang Plastic

Yuyao Longzhuang Plastic, founded in 2002 by a collective of seasoned engineers, stands at the forefront of acrylic injection technology.

With unwavering passion, the company strives to bring forth exceptionally streamlined curves and geometrical angles, creating an exquisite showcase for active serums and botanical oils with optimal refractive effects.

Their commitment to industrial leadership extends to pioneering innovations that challenge the traditional use of glass, reflecting a dedication to pushing the boundaries of cosmetic packaging.

Through years of expertise and a relentless pursuit of excellence, Yuyao Longzhuang Plastic has become synonymous with cutting-edge solutions and unparalleled creativity in the realm of cosmetic bottle manufacturing.

8.4 Guangzhou Zimay Plastic

Certified under ISO 22716 GMP standards, SoMakeup operates an impeccable workshop outfitted with CNC machines and dust-free assembly rooms.

Their experience since 2008 producing professional-grade brushes shines through bespoke offerings that are exactly tailored to customer needs and beauty objectives.

8.5 Shaoxing Yicai Plasticstd

Earning multiple accolades for pioneering biologically derived packaging materials through cunning innovation executed impeccably on precision manufacturing machinery, Shaoxing Yicai Plastics constantly enhances capabilities suiting 21st-century consumer expectations on sustainability without aesthetic sacrifice, evidenced by charming metallic color gradients on PET vessels with swirling natural biopolymer composite patterns.

8.6 Hangzhou Yuhang Zhenhua Daily Chemical Glass

Garnering awards for glass craft mastery manifesting divine ombre variations inspired by galaxies and nature’s iridescent wonder, Zhenhua artisans adopt fully customized imagery into exquisite packaging eliciting gasps once revealed housing luxurious contents equally as mesmerizing. Their 30-step finishing process polishes delicate edges as smooth as luxury feels.

8.7 Xiamen Tiumsen Cosmetics.

Expanding notions on material limitations, Xiamen fuses technical prowess with daring creativity through signature in-bottle 3D casting empowering cosmetic brands to encapsulate bespoke swirls, flowers, and kaleidoscopic universes once perceiving acrylic purely as transparent. Collaborating passionately from sketches onwards makes visions a reality through their manufacturing finesse.

Epitomizing scientific minimalism with 15ml petite dropper bottles and unadorned cylindrical vessels ensuring formula eminence shines ahead of mere containers, Zhejiang Cosme foregoes superficial embellishments in favor of intellectual partnerships and co-engineering distinguished solutions with functional esteem greater than parts. Streamlined packs ship worldwide from their automated 40,000 sqm plant.

8.9 Guangzhou Panyue Packing.

Redefining packaging scope by conquering mass manufacture of dual-chambered airless acrylic bottles with bakelite over shells through synchronized mechanical choreography, Guangzhou Panyue furnishes major brands with multifaceted products as imaginative as the cosmetic contents within. Thanks to their technology investments, no custom concept feels beyond reach.

8.10 Guangzhou Jiaxing Glass Products.

Celebrated inheritors preserving generational glass crafting traditions while advancing production technology to economically sustain intricate techniques otherwise fading over time, Guangzhou Jiaxing artisans subtly polish inimitable bottles coveted by high priests of skincare for their unworldly aurora ricocheting refractions of purity and brilliance through every faceted edge and surface. Perceived value transcends coins.

Here is why choose Huntersourcing as your cosmetic bottle China sourcing agent.

9. Why Choose Huntersourcing As Your Cosmetic Bottle China Sourcing Agent?

With over 12 years of importing expertise from China, Huntersourcing offers unparalleled advantages guiding cosmetic brands through streamlined procurement of custom bottles, jars, and accessories manufactured diligently to exact specifications. We simplify the entire process.

Our specialized industry agents speak the language of beauty packaging intrinsically given years of assisting global firms across hundreds of OEM projects. We translate intricate technical requirements into actionable specifications that Chinese factories comprehend rapidly thanks to deep manufacturing familiarity. This bridging prevents miscues or misalignments.

We further appoint compliant manufacturing partners already proven capable of accommodating niche vertical needs through custom mold fabrication, reliable assembly, and stringent quality assurance practices. Our connections to access high-grade factories are unknown publicly. Audit rigor then verifies conditions satisfying expectations.

Throughout engineering iterations, we secure prompt feedback and suggested enhancements so brands refine visionary designs efficiently toward intended goals. During subsequent mass production, our quality technicians enforce process controls through site supervision and outgoing inspections rejecting inferior samples falling below project standards.

For delivery coordination, we consolidate shipments across factories for savings, rapidly clear export customs formalities by leveraging trade tools, and negotiate rates ensuring secure transport to final destinations. Supply chain orchestration makes overseas procurement feel local.

Trust in our cosmetic packaging import mastery from first sketches to logistics optimization and everything between across thousands of breeding beauty products entering the world.

Conclusion

When resourcing quality cosmetic bottles with an elevated user experience matching formula investments, importing custom China packaging tailored and tested rigorously presents an immense opportunity for differentiation and savings.

Factories now creatively develop au courant containers rivaling top French perfumers through globally competitive manufacturing conditions married with century-old productive prowess manifesting affordable excellence.

The latest techniques and innovative specialization profiled among these renowned Chinese cosmetic bottle manufacturers await harnessing for new formulation product launches or rebrands needing a new exterior vessel adequately conveying mystique promises finally fulfilled inside. Through diligent verification of capabilities beyond digital gloss, strategic partnerships bloom.

Get The Experts on the Job

Contact expert China beauty import agents to begin discussing your cosmetic packaging visions and receive matched recommendations on suppliers equipped to adeptly transform imaginative concepts into mass manufacturable reality through precision and care-evoking delight. Launch products as special as formulas within.

Related Post

Furniture is a must for an office or a home. It is available at varying price points as Read more

Wood is extensively used in making furniture around the world. Wood can be molded in any shape or Read more

In the current market condition, a major portion of the world's consumption depends on China. The product range Read more

Contact Us Get Free Quote!

* Please kindly fill out the form for inquiry

* we will reply to your inquiry within 24hours