Top Plastic Bag Sealing Machine Manufacturers in China

Sourcing suitable sealing machine manufacturers from China may prove to be one of the vital tasks for industries seeking to acquire quality and affordable tools. Here is a comprehensive buying guide to help you through the process of finding the best sealing machine suppliers:

1. What Is Sealer Machine?

2. How Do You Choose Your Sealing Machine?

3. Production Process

4. How Many Types Of Sealing Machines?

5. How Sealing Machine Works?

6. Which Sealing Machine Is Best?

7. How To Choose A Sealing Machine Supplier?

8. Where To Buy Sealing Machine From China?

9. Top 10 Sealing Machine Suppliers In China

9.1 Guangzhou Leva Packaging Equipment Co., Ltd

9.2 ShineBen Machinery Co., Ltd

9.3 Hualian Machinery Group Co., Ltd

9.4 Guangdong XTIME Packaging Equipment Co., Ltd

9.5 Utien Pack Co, Ltd

9.6 Wenzhou Lianteng Packaging Machinery Co., Ltd

9.7 Wenzhou Huaqiao Packing Machine Factory

9.8 Shenzhen Penglai Industrial Corporation Limited

9.9 Shanghai Joygoal Food Machinery Co., Ltd

9.10 Rui’an Yidao Machinery Co., Ltd.

10. Sealing Machine FAQ

11. Why Choose Huntersourcing As Your Sealing Machine Sourcing Agent?

1. What Is Sealer Machine?

It is an equipment used for closing and sealing of different types of packaging. These machines are employed in other sectors to guarantee that various end products are sealed appropriately to ensure they are protected and remain fresh.

Sealing also acts as evidence that a product has not been tampered with. Sealer machines are crucial in sealing products to ensure they are not destroyed or contaminated.

Sealing machines also ensure that a product has a professional look. That is why the selection of the sealer machine directly depends on the type of packaging material, the needed strength of the seal, and the scale of production.

The types of sealer machines are many but differentiated by features to suit the application and material to be used.

2. How Do You Choose Your Sealing Machine

Choosing a sealing machine involves considering several factors based on your specific needs and the nature of your product packaging:

2. 1 Application

Determine the type of packaging you will be sealing:

• Bag / Pouch

For example, snack, grain, powdered or liquid products such as flavored wafers, biscuits, rice, coffee, chocolate, drinks, soup, or sauce. Equipment for such an application comprises heat sealing or vacuum since it involves closing the bag.

• Blister Pack

Quite popular in the context of medicine production, electronics, and other small appliances and consumer goods. Sealing machines for this type of blister packets are developed to be so.

• Bottle / Jar

Used for liquids, powders, or granulated products. Induction sealing machines are often used for these applications.

• Box / Carton

This one is preferred on large or bulk items. It is usually preferable to apply carton sealing machines.

• Can

May be employed in food, drink, or industrial items. Sealers or double-seam sealers can be used here. Appropriateness depends on the application.

2. 2 Technology

Select the sealing technology that suits your packaging material and product:

• Impulse Sealing

Explores a quick energy boost to decrease the temperature of the sealing element. Ideal for thermoplastic materials and very frequently used in the sealing of bags and pouches.

• Induction Sealing

Induction sealing employs an electromagnetic induction to heat and seal the material. Sometimes applied to seal the lids of bottles, jams, and other jars having lids that are screwed on.

• Infrared Sealing

The sealing uses infrared radiation to heat and then seal the material in the process of carpet backing application. It is suitable for delicate materials.

• Laser Sealing

Uses laser beams to create a seal. This technology is accurate and works for many types of materials.

2. 3 Operation

Decide on the level of automation needed:

• Automatic

Most suitable for use in production lines that require many units to be produced in a comparatively short amount of time. These machines are almost fully automatic and can work through large volumes of clothes at once.

• Semi-Automatic

The one suitable for moderate production volumes. It is automatic but a little more flexible and allows you to have some control.

• Manual

Manual sealing machines are perfect for small-scale production or where volumes of production require a very special kind of control. They are cheaper and easy to use, though they are not ideal for large-scale production.

3. Production Process

The information about the specific production process of the manufacturer can inform about the quality and trustworthiness of the products. Evaluate the following aspects:

Well-selected Raw Materials

Ensure that the manufacturer employs high-quality raw materials. That may involve ensuring the origin of the materials used to compare them to the standard industry practice.

Search for quality standards as indicated by the availability of certain certifications like ISO.

Parts Processing & Inspection

Assess the manufacturer’s capabilities in processing parts with precision. This frequently results in the use of complex machinery and technology, all in a bid to perform a task.

Ask the potential suppliers about the procedures that are employed to determine if each part complies with the specifications that are regarded as standard. This can be done by using traditional methods on a computer like Computer Numerical Control machining and laser cutting just to mention but a few.

Intricate Hand Assembly

Assess whether the manufacturer has skilled workers who perform the assembly work in the production line. Hand assembly can be important, especially when it comes to creating correct and accurate fitments.

Go to them and inquire about their assembly line process on how they achieve order and quality.

Careful Machine Inspection

Ensure that the manufacturer has an efficient machine testing system that properly examines the machines to identify any problems before they are exported.

Examine the process of machine inspection, including functional tests, durability tests, and safety tests.

Strict Trial & No-load Run Test

Ensure the manufacturer gives the absolute best trial runs and no-load tests to verify its capacity in those scenarios.

You can ask for documents or reports on these tests to assess the outcomes and possibly the compliance with your needs.

Final Polishing

The last process of polishing is vital especially in the artistic look of the machine, and efficiency too. Ensure the manufacturer has this in mind.

Physically inspect the surface finish quality of the machines. It should be ascertained that the equipment is in perfect condition with no flaws and is fit for use as soon as it is received.

4. How Many Types Of Sealing Machines?

Ensure you know the full types of sealers before you choose a manufacturer to buy from. Different manufacturers specialize in various types of machines. So, identify which ones align with your needs.

Sealing machines are available in different types:

• Heat sealing machine

Heat-sealing machines seal various types of materials together using heat. The heat bonds several types of materials used in packing companies.

• Plastic sealing machine

The machine is made to seal plastic materials together. These machines are used in the packaging industries.

• Cup sealing machine

A cup sealing machine secures and closes the tops of cups mostly used in the packaging of beverages and foods.

• Bottle sealing machine

Bottle sealing machines are for corking bottles at the neck. That helps ensure that the cap is tightly closed.

• Hand-sealing machines

These are hand-held machines that heat and seal bags or pouches using people’s hands to operate controls on the machines.

• Pouch sealing machine

The machine is for sealing corks, pouches, bags, or sachets, especially those applied in the packaging of food products.

• Foil sealing machine

They place a seal on lids on containers, most of which are used in the packaging of milk products and other foods.

• Cap sealing machine

The machine seals caps on the bottles or containers making it difficult for it to be stamped with by anyone other than the manufacturer.

• Tray sealing machine

The machine seals trays with film–poly, mostly utilized to cover ready-to-eat foods.

• Cover sealing machine

The machine seals tightly, fits onto containers or jars, and helps to maintain the freshness of the content it covers.

• Jar sealing machine

Lids seal onto jars it is majorly used in the process of canning and food preservation.

• Glass sealing machine

The machine seals glass containers or jars used in sectors such as pharmaceuticals or food processing.

• Box sealing machine

The box sealing machine secures the enclosure of the cardboard box using adhesive tapes or glue as the case may be.

• Tube sealing machine

The sealing machine closes the ends of tubes, which are utilized especially in the cosmetic and/or pharmaceutical industries.

• Filling and sealing machine

Such a machine is used to fill containers such as cups, bottles, and pouches with the product and, at the same time, seal the container.

• Vacuum sealer machine

Just like its name suggests, this machine expels air from products and seals packages.

5. How Sealing Machine Works?

A sealing machine uses force and heat to join two materials to each other or to seal a material that is pumped through a tube. Here is a basic overview of how it typically operates:

• Heat source

The heating of most sealing machines can be done using elements like a heated bar or heated plate. The heat alters the state of the materials to be sealed. It could be plastic, foil, or any other flexible material.

• Pressure application

To accomplish this, the machine puts down pressure on the materials to create a closer and proper fit. It can be exerted in the form of a push/pull force, using compressed air in cylinders or even manual levers, depending on the type and size of the machine.

• Sealing process

When the materials are inserted in between the heating element or pressure mechanism, then the heat makes the surfaces that are intended to be sealed softer. Pressure is then applied to compact the materials by forcing them against each other with a firm pressure.

• Cooling and solidification

In some cases, especially for the sealed area, they take time and cool or solidify after a brief process called sealing. That helps to guarantee that the seal is not damaged and is in its correct state when placed on the product.

• Types of seals

Sealing machines can come with various characteristics that help to create different types of seals as flat seals, embossed seals, or cuts if the bags have to have some tear-open elements.

• Control and automation

Most of the present-day sealing machines are computerized. Automation ensures that the joints are sealed in such a manner that results in consistent and effective sealing on every project executed.

In general, sealing machines are multifunctional equipment, which is used in packaging industries, in the production line, and in some other sectors where the closure of some material is vital.

6. Which Sealing Machine Is Best?

Choosing the best sealing machine depends on your specific needs, such as the type of packaging material (e.g., plastic bags, pouches), the volume of packaging you need to handle, and any specific features or functionalities you require.

Assess the challenge and establish the precise specifications of your business. Selecting a sealing machine can be easier if you consider factors such as:

• Type of sealing

Depending on the packaging material, it is vital to establish the kind of sealing that would be useful, whether it is heat, vacuum, impulse, or the continuous band seal.

• Material compatibility

Ensure the machine of intended use will accommodate the types of materials, including plastic, polyethylene, and aluminum foil, and the thickness you will be sealing.

• Ease of use and maintenance

Select machines that are also easy to use and simple to assemble. The machine should also be easy to service. For instance, choose machinery with reduced blind spots. Some machines may need the services of a mechanic for routine check-ups, or sometimes, the parts have to be replaced.

• Brand and reviews

Check the credibility of the brands to know about their longevity, efficiency, and service quality that its customer support offers you.

7. How To Choose A Sealing Machine Supplier?

When selecting a sealing machine supplier, there are several vital factors to look for.

• Experience

Ensure that you find the suppliers with the best reputation in offering sealing machines. It is primarily true that experience leads to more reliability in understanding the currently offered products on the market.

• Innovative Design

With sealing needs enabling the engaging of a variety of suppliers, be sure to consider suppliers who provide designs and technologies that suit your sealing needs. That makes your operations to be efficient and effective.

It is with great advantage if the suppliers provide options for developing sealing machines tailor-made to the specific client. It can increase efficiency and accommodate specific orientations and other specifications.

• Installation Guide

A supplier that provides installation support and assistance assures you that the sealing machine is installed correctly and is in the right condition when purchased.

• Quality Machines

Quality should be a priority. Select the suppliers that supply high-quality sealing machines whose durability and performance are proven.

• Spare Part Kits

This partly depends on the availability of spare parts since their unavailability can cause a machine to remain idle for a long time in case of a breakdown. Ensure the supplier provides encyclopedic spare part kits.

• Technical Support

Having good technical support is key since the technical needs for any problem or maintenance are expected to be attended to as soon as possible. Therefore, only choose a supplier who offers technical support to its customers.

• Warranty

A Strong warranty shows that the supplier has confidence in the product. Ensure that the warranty terms are spelled out properly and comprehensibly to provide the warranty that you would like to have.

• Customer Service

Good relations with customer care also make a big difference regarding the outcome of what you want to do. Some of the things shoppers should focus on include customer care, which must be friendly and available to assist.

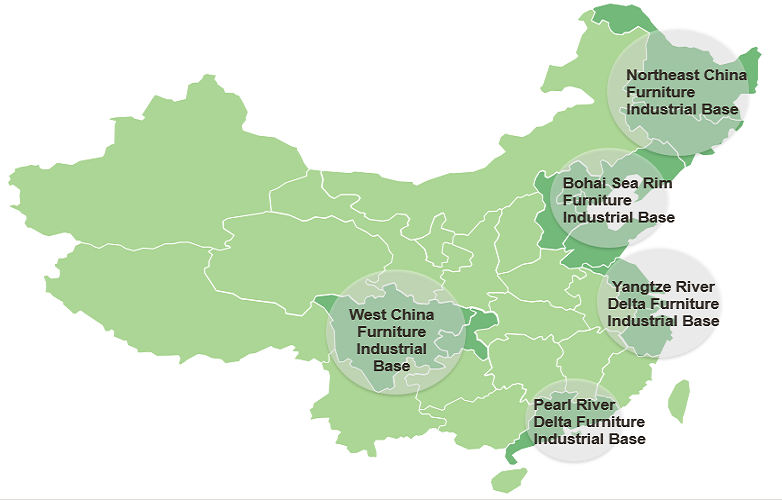

8. Where To Buy Sealing Machine From China?

Now, if you are interested in purchasing a sealing machine and you are sourcing for it from China, then you can get it from some of the popular sites.

Furthermore, employing the services of a sourcing agent such as Huntersourcing is advisable because it can help in sourcing and guarantee suppliers’ credibility in China. Each of them has its advantage over others and it depends on the nature of the order and needs and expectations (for example, the number of posts, their approach, or the price).

Below are some popular places where you can find sealing machines from China:

1. alibaba.com

2. made-in-china.com

3. dhgate.com

4. globalsources.com

5. aliexpress.com

6. chinabrands.com

7. Huntersourcing -China sourcing agents

9. Top 10 Sealing Machine Suppliers In China

It is often a challenge for those doing import business to find trustworthy sealing machine manufacturers in China. Here are a few well-known and reliable plastic bag sealers suppliers based in China

9.1. Guangzhou Leva Packaging Equipment Co., Ltd.

Guangzhou Leva Packaging Equipment Co., Ltd. is a packaging equipment company well-recognized in this field. The company deals with different types of packaging machinery, including sealing machines.

Guangzhou Leva Packaging Equipment Co., Ltd. is a China-based company situated in Guangzhou. Sealing machines are one of the several packaging machinery solutions Bluebird offers. The supplier enjoys a good reputation for delivering quality products and services in the domain of packaging.

Regarding details that are rather specific or any other questions, it would be more helpful to check their official website or apply for the required information directly. Visit https://www.levapack.com/ for more details/.

9.2 ShineBen Machinery Co., Ltd

ShineBen Machinery Co., Ltd. is also an approved seller in the machinery line that focuses its products on sealing machines and related products. It is based in the Guangdong province of China. The company deals in the production of sealing machines, packaging equipment, and related products.

ShineBen Machinery Co., Ltd. is one of the best plastic bag sealing machine manufacturers, which provides clients with systematic sealing equipment and types of sealing methods according to their special fields and requirements.

To get more specific information about them and the various services, a visit to their website or contact them would be most critical in providing this information. Click https://www.shinebenmach.com/ to see what the supplier offers.

9.3 Hualian Machinery Group Co., Ltd

Hualian Machinery Group Co., Ltd is one of the leading poly bag sealing machine suppliers situated in China.

They provide various types of sealing machines: versatile vacuum food sealer machines, impulse sealing machines, ongoing band sealing machines, and automatic sealing machines.

Hualian Machinery Group company is well established as a manufacturer of efficient and superior quality equipment for food packaging, pharmaceuticals, electronics, and other sectors.

These principles include factors such as innovation and customer satisfaction making it a reputable company to that business seeking sealing solutions.

Click https://www.hualianmachinery.com/ to discover what one of your favorite impulse sealers suppliers has in store for its customers.

9.4 Guangdong XTIME Packaging Equipment Co., Ltd

Guangdong XTIME Packaging Equipment Co., Ltd. is categorized as the leading hand-sealing machine manufacturer to trust. They offer a packaging production line that consists of sealing equipment, filling, and labeling equipment.

They have several competitive strengths. For instance, the company has more advanced technology than competitors, XTIME’s quality control or assurance, and a recognized customer service attitude. The company provides clients with solutions that address unique packaging requirements.

The company updates its offers, discounts, and available products at https://www.xtpackagingmachine.com/.

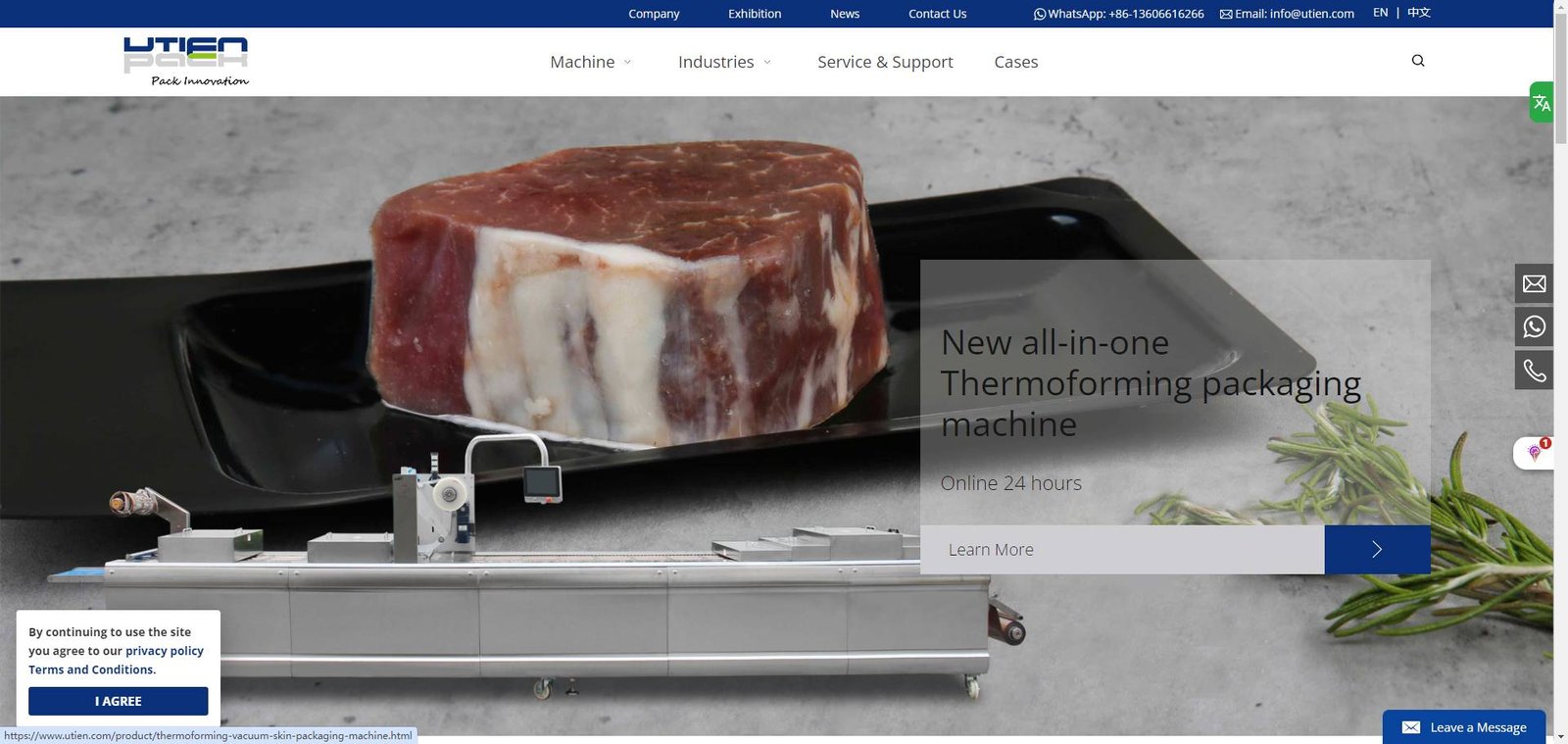

9.5 Utien Pack Co, Ltd

Utien Pack Co., Ltd. is one of the leading vertical form fill seal machine manufacturers located in Shaoxing, Zhejiang, China. They concentrate on packaging machinery, especially sealing and vacuum packaging equipment.

Packaging machines that this band sealer machine manufacturer deals in consist of vacuum packing machines, thermoformed packing machines, and sealing machines. They are designed for various uses such as in the food, medical, and car industry’s packaging sectors. Utien Pack provides a diverse area of sealing machines for sealing various kinds of material used in the packaging industries.

The sealing machine supplier has adopted quality production and testing to ensure that the machines for laundry are of high quality. Customized services to satisfy particular clients’ requirements are likely available; packaging’s flexibility may also be available.

For more detailed information or specific product inquiries, you can visit https://www.utien.com/.

9.6 Wenzhou Lianteng Packaging Machinery Co., Ltd.

Wenzhou Lianteng Packaging Machinery Co., Ltd. is a Wenzhou, Zhejiang, China original vacuum sealer supplier. The company deals in different packaging machinery and provides superior machinery for effective packaging.

It is one of the heat sealing machine manufacturers with an inquiry system where customers can ask questions about a product and give comprehensive product information on the firm’s website. From this supplier, you can select the packaging machinery that relates to filling machines, sealing machines, labeling machines, and packing machines.

The supplier deals in domestic as well as global markets. It focuses on stringent quality manufacturing and insists on the quality standards of the products.

For more details or specific product inquiries, you can visit their profile through https://www.ltpk.com/. This webpage presents all the basic information about this company and its product profiles.

9.7 Wenzhou Huaqiao Packing Machine Factory.

Wenzhou Huaqiao Packing Machine Factory is one of the leading form fill seal machine manufacturers situated in Wenzhou, Zhejiang, China. The firm deals in different packaging machines. They provide quality and durable products to serve the different packaging requirements.

It focuses heavily on the production of the machines for sale, and the firm exercises immense care in the quality of its products. In addition, the manufacturer has the means to package exceptional services aimed at fulfilling the needs of every client, hence increasing operational flexibility.

The company’s products are sold in many countries because they meet international requirements and legal acts. The company makes provision for inquiries relating to products and provides general and specific information on products on its website. For more detailed information or specific product inquiries, you can visit https://www.kunba.biz/.

Shenzhen Penglai Industrial Corporation Limited is another prominent name among plastic bag sealing machine suppliers based in the People’s Republic of China. The company provides packaging machinery of high quality for numerous industries and purposes of use, among them being Shenzhen Penglai Industrial Corporation.

The company has established a broad network of operations, internationally, fulfilling vital customer requirements of reliable products and efficient services. Penglai Industrial Corporation pays much attention to the innovation of packaging technology and applies various superior technological features to increase the performance of packaging products and better qualities.

Visit https://www.sealermachines.com/ and discover why this company is one of the best poly bag sealing machine manufacturers in China.

9.9 Shanghai Joygoal Food Machinery Co., Ltd.

The specialization area of Joygoal Food Machinery Co., Ltd is food packaging machinery, commitment to automation, and focus on delivering high-quality, customized solutions to meet the evolving needs of the food industry. They are enhancing their product quality and business expertise, which makes them suitable for boosting packaging solutions.

It targets a wide range of customers within the global market with very affordable prices for its products and efficient response to the client’s complaints.

It is among the induction sealing machine manufacturers that follow strict standard operating procedures in the production line to provide dependable and long-lasting machines of high standards.

Joygoal has customization services to meet the client’s needs and to ensure the machinery meets required packaging demands and types.

Click https://www.shjoygoal.com/ to access its products, prices, and offers.

9.10 Rui’an Yidao Machinery Co., Ltd

Rui’an Yidao Machinery Co., Ltd deals in a series of packaging machines that can be applied in a variety of fields. They offer their clients standard products. It is one of your go-to pouch-sealing machine manufacturers with tailor-made solutions for specific packaging needs.

Policies of quality control are also strongly developed in the company. All its production, in turn, is aimed at the constant quality of products, their durability, and reliability.

They are popular for being strongly associated with the cheap production of packages while still retaining quality and standards that are appealing to the various business executioners.

The leading company Rui’an Yidao Machinery Co., Ltd, headquartered in Quanzhou, China, is customer-oriented. It provides efficient customer support services and technical support to answer their questions and guarantee the trouble-free functioning of their equipment.

Visit https://www.yidaomachinery.com/ for details

10. Sealing Machine FAQ

10.1 How to use plastic bag sealing machine

To operate a plastic bag sealing machine, the following steps should be taken:

• Prepare your plastic bag

Preparation aids in developing a uniform seal.

• Adjust the machine settings (if applicable)

Depending on the type of the sealing machine (heat sealer, impulse sealer, etc.) set the temperature, sealing time (for impulse sealers), and other parameters according to the manufacturer’s description.

• Activate the sealing process

For these machines, press the button or lever that would start the sealing. The machine will use heat and pressure to make the seam, that is, make a seal.

For impulse sealers, ensure that you press and hold down the sealing arm until the light comes on to show that the sealing process is done. Let go of the arm after sealing.

• Allow cooling (if applicable)

In certain sealing machines, the sealing operation must be followed by less CO2 gas top-up and then cooling for a short time before the seal gets locked properly. Take time to cool the sealing as recommended by the manufacturer.

• Inspect the seal

After cooling it if necessary, and once the sealing process is done, confirm that the seal is done properly, almost uniformly, and is strong enough to hold a desired object or substance. Check that there are no spaces between the existing material and the seal where it has not been used.

Remove the sealed bag and cut off any excess material they may have if needed.

• Repeat for additional bags

When sealing multiple bags, repeat the process for each bag. It is advisable to keep the settings of the sealer in check and the quality of the seals created.

10.2 What is an induction sealing machine?

An induction sealing machine uses electromagnetic induction to make the metal foil seal at the lip of a container to heat and act as tamper-proof packaging.

10.3 What is an impulse sealing machine?

An impulse sealing machine works by passing a very short electrical current through the sealing wire or element to melt the material and fuse it to form a seal.

10.4 What is a cup sealing machine?

A cup sealing machine is a piece of trading equipment that puts a lid on cups carrying liquids or semi-solids like bubble tea or yogurts through heat or pressure.

10.5 What is a band-sealing machine?

A band sealing machine makes use of a strip of heat-sealable material, a band, or tape in sealing bags and pouches, respectively, from top to bottom.

10.6 What is the best vacuum sealer?

Choosing the best vacuum sealer depends on your specific needs and preferences, as well as the features that are most important to you. Consider the sealing power, user friendly, how it is maintained, and the sealing type.

10.7 What is a heat sealing machine?

The machine creates a seal by melting thermoplastic materials together. It is recommended for packaging applications in food, medicines, and industrial products.

10.8 What do we mean by an automatic vertical form fill seal (VFFS) packaging machine?

The vertical form fill seal machine, or VFF, is a useful packaging equipment that combines forming a bag out of a flat roll of film, filling it with the product, and sealing the bag in one operation.

10.9 What are the additional benefits of a sealing machine?

Here are some other benefits that one can derive from sealing machines other than sealing bags or packaging materials.

• Extended shelf life

Sealing machines are useful in that they provide a tight enclosure to food items that, in turn, lasts longer and does not go bad easily.

• Improved product presentation

It modifies the aesthetics of products because it throws a positive outlook on the products by attractively sealing them.

• Increased product safety

Packaging sealing machines enable products to remain protected from contaminants or any external influence likely to affect them while in storage or transit.

• Cost efficiency

These machines are easy to use and provide quick and accurate sealing of bags. That increases the production rate. That cuts down on the amount of labor required and enhances the rate of production as compared to endeavors that involve manual sealing.

• Versatility

Sealing machines are versatile in the type of packaging materials they work on. They can also work on different sizes of packages. So, they are useful for several industries including food industries, pharmaceuticals, industrial parts, and many more.

• Environmental benefits

Properly sealing the packaging always minimizes cases of food spoilage due to exposure to air, which may lead to food going bad. That helps in the sustainability of the business by reducing cases of disposal of bad or expired stocks.

• Ease of use

Most of the sealing machines in operation today come with easy-to-use interfaces and controls that operators can manage easily, irrespective of the level of experience they have.

10.10 What is the best food vacuum sealer?

The considerations to guide you to the best food vacuum sealer must include your sealing requirements. Another consideration must be the sort of food you intend to seal that is either moist or dry and other feature preferences.

While selecting a food vacuum sealer, there are a few important factors that one should look for, such as the sealing force, utility, maintenance, and additional features like the bag cutter and roll storage. To ensure that you get the best food vacuum sealer, you should read customer reviews and compare the specifications.

11. Why Choose Huntersourcing As Your Sealing Machine Sourcing Agent?

Huntersourcing is a well-known sourcing agent in China that specializes in helping businesses find reliable suppliers for various products, including sealing machines. Choosing Huntersourcing as your sealing machine sourcing agent from China offers several advantages:

Sourcing is one of the major processes where Huntersourcing consultants can guide you through potential complications and subtleties.

• Rich experience

Huntersourcing has the appropriate experience in sourcing and logistics and also the Chinese market can benefit you in this regard.

• Efficient team

They have a dedicated team that is responsible for providing meaningful communication, fast processing of sourcing requests, and the overall satisfactory resolution of the necessary sourcing demands.

• Market research

Huntersourcing obtains up-to-date information about possible and trustworthy suppliers and trends in the area of sealing machines.

• Product research

They help in product search and ensure that the sealing machines obtained are in line with your order and quality check.

• Supply chain management

Starting from the supplier evaluation stage to the final delivery stage, Huntersourcing is very efficient in the management of supply chains.

• Factory audit

They also conduct very competent factory audits to check on the competency of the suppliers, quality assurance, and compliance with the law.

• Design and development

It is worth noting that Huntersourcing can contribute to primary and custom design as well as develop sealing machines as per your specifications.

• Sample and price negotiation

The sample acquisition also lies in their jurisdiction, which entails reaching out for prices that are most favorable for your study while maintaining quality.

Quality control measures for sealing machines are put in place by Huntersourcing at all times during production to allow for the delivery of the best products.

• Shipping & logistics

They are responsible for transportation, coordination of transportation, as well as documenting and dealing with documents required in the transportation process to ensure the timely delivery of material or products.

• Customs clearance

The advantages of Huntersourcing include the support of customs formalities to minimize the time spent on the procedure and compliance with the established rules of imports.

Huntersourcing is a sealing machine sourcing agent that will provide a full range of assistance so you are not left in the middle of the sourcing process.

Contact Huntersourcing today to discuss your sealing machine sourcing needs and benefit from their expertise in sourcing from China. Visit their website or reach out via email/phone for a consultation tailored to your requirements.

Related Post

Furniture is a must for an office or a home. It is available at varying price points as Read more

Wood is extensively used in making furniture around the world. Wood can be molded in any shape or Read more

In the current market condition, a major portion of the world's consumption depends on China. The product range Read more

Contact Us Get Free Quote!

* Please kindly fill out the form for inquiry

* we will reply to your inquiry within 24hours