Importing From China: A Look into Laser Cutting Machine Manufacturers

Finding the best laser cutting machine manufacturer from China requires research and due diligence. Consider factors such as quality, price, technology, and after-sales support. Look for reviews and case studies, compare specifications and prices, and visit trade shows to meet with manufacturers.

Trustworthy sources include industry associations, online marketplaces, and sourcing agents. Make an informed decision by considering all factors and communicating directly with the manufacturer.

1. What Is Laser Cutting Machine?

2. What Are The Basics Of Laser Cutting Machines?

3. What Is The Advantage Of A Laser Cutting Machine?

4. How Laser Cutting Machine Work?

5. What Are The Applications Of A Laser Cutting Machine?

6. What Will Be The Growth Of The Laser Cutting Machine Market?

7. Laser Cutting Machine Brand

8. What Are The Various Types Of Laser Cutting Machines?

9. How To Use Laser Cutting Machine?

10. Where To Buy Laser Cutting Machine?

11. How Do We Choose Laser Cutting Machine Manufacturers?

12. Import Laser Cutting Machine from China FAQ

12.1: Why import a laser cutting machine from China?

12.2: What are the payment terms when importing a laser cutting machine from China?

12.3: How long does it take to import a laser cutting machine from China?

12.4 Which laser cutting is better, CO2 or fiber?

12.5 How to maintain a fiber laser cutter?

12.6 What are some disadvantages of laser cutting?

13. Why Choose Huntersourcing As Your Laser Cutting Machine Sourcing Agent?

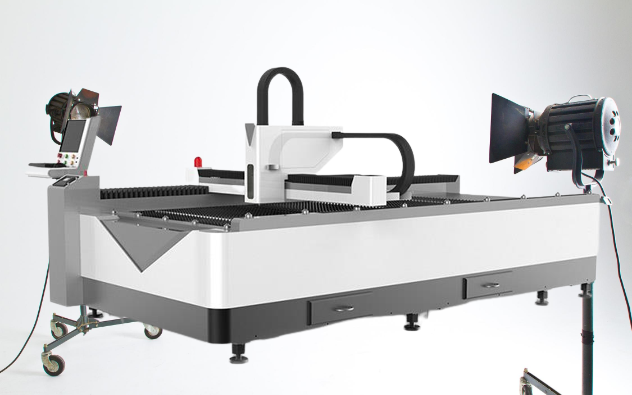

1. What Is Laser Cutting Machine?

A laser cutting machine is a type of computer-controlled machine that uses a laser beam to cut materials such as metal, plastic, wood, and textiles. The laser beam is generated by a laser source (usually a gas laser or solid-state laser) and is directed through a series of mirrors and lenses to focus it into a very narrow, intense beam. When the beam comes into contact with the material, it melts, burns, or vaporizes it, cutting it into the desired shape.

Laser-cutting machines are commonly used in manufacturing, metalworking, and other industries to produce precision parts and to cut materials into complex shapes. The high precision and speed of laser cutting make it an attractive alternative to traditional cutting methods such as sawing, drilling, and milling.

2. What Are The Basics Of Laser Cutting Machines?

Laser cutting is a technology that uses a laser beam to cut materials, including metals, plastics, and wood. The process is controlled by a computer numerical control (CNC) machine, which directs the laser beam to the material surface, following a programmed path to create the desired shape.

Here are the basics of laser-cutting machines:

2.1 Types of lasers: There are different types of lasers used in laser cutting machines, including CO2, fiber, and solid-state lasers. Each type of laser has its own advantages and disadvantages, and the choice of laser depends on the specific cutting requirements and the material being cut.

2.2 Power source: The laser used in laser cutting machines is generated by a power source, such as an electrical discharge or a flashlamp. The laser power determines the cutting speed and the thickness of the material that can be cut.

2.3 Focusing lens: The laser beam is focused onto the material surface by a focusing lens. The lens is adjustable, allowing the focus point to be changed, which affects the cutting quality and the laser’s ability to cut through thicker materials.

2.4 Gas supply: To assist the cutting process, a gas supply, such as nitrogen or oxygen, is used to blow away the melted material. The gas supply also helps to cool the material, preventing it from catching fire and distorting the cut.

2.5 Workpiece handling: The material to be cut is usually secured to a flat surface, such as a bed or table, and is held in place by clamps or a vacuum. The laser cutting machine is equipped with a cutting head that moves over the surface of the material, following the programmed path, to create the desired shape.

2.6 Software: Laser cutting machines are controlled by computer software, which converts the desired cutting path into instructions that can be followed by the CNC machine. The software also controls the laser power and the gas supply, ensuring that the cutting process is carried out safely and efficiently.

3. What Is The Advantage Of A Laser Cutting Machine?

A laser cutting machine has several advantages over traditional cutting methods, including:

3.1 Precision: Lasers are capable of cutting with high precision and accuracy, which is especially important for intricate or detailed designs.

3.2 Speed: Lasers can cut much faster than traditional methods, making them ideal for high-volume production runs.

3.3 Flexibility: Lasers can cut a wide range of materials, including metals, plastics, wood, and more, making them versatile and ideal for many different applications.

3.4 Consistency: Because lasers cut with such precision, the end result is more consistent and uniform compared to traditional cutting methods.

3.5 Clean cutting: Lasers create a clean, smooth edge, which requires less finishing work than traditional cutting methods.

3.6 Low maintenance: Lasers require minimal maintenance compared to traditional cutting methods, which can be costly and time-consuming.

Overall, a laser cutting machine provides greater efficiency, precision, and versatility compared to traditional cutting methods, making it an excellent choice for many industrial and manufacturing applications.

4. How do Laser Cutting Machines Work?

Laser-cutting machines work by directing a highly focused laser beam onto the surface of the material being cut. The laser beam is generated by a laser source (usually a solid-state laser) and is directed through a series of mirrors and lenses that focus the beam on a small, intense spot. This focused laser beam melts, vaporizes, or burns away the material in a precise, controlled manner, allowing the machine to cut complex shapes and designs with a high degree of accuracy.

The laser cutting process typically involves two main stages: marking and cutting. In the marking stage, the laser beam is used to produce a small, shallow mark on the surface of the material. This mark acts as a reference point for the cutting process, allowing the machine to accurately position the laser beam for each subsequent cut.

In the cutting stage, the laser beam is used to melt, vaporize, or burn away the material along a pre-determined path, producing a clean, precise cut. The speed at which the laser beam moves and the power of the laser determine the thickness of the material that can be cut. Thicker materials typically require higher laser power and slower cutting speeds.

The laser cutting machine is typically controlled by a computer numerical control (CNC) system, which uses a set of pre-programmed instructions to guide the movement of the laser beam and the material being cut. This allows for complex cutting patterns and designs to be produced with a high degree of accuracy and repeatability.

Laser-cutting machines are used in a variety of industries, including aerospace, automotive, electronics, and construction, for cutting and shaping a wide range of materials, including metals, plastics, and composites.

5. What Are The Applications Of A Laser Cutting Machine?

A laser cutting machine is a versatile tool that is used in a variety of applications across various industries. Some of the most common applications of laser-cutting machines include:

5.1 Manufacturing and fabrication: Laser cutting machines are widely used in the production of metal and plastic products, such as automotive parts, electronics, and machinery components.

5.2 Aerospace and defense: Laser cutting is used to produce precision parts for the aerospace and defense industries, such as aircraft fuselages, engine components, and missile systems.

5.3 Medical equipment: Lasers are used to cut and shape medical implants and devices, such as pacemakers and surgical instruments.

5.4 Construction and architecture: Lasers are used to cut and shape materials for building and construction, including metal and glass for curtain walls, steel beams, and more.

5.5 Printing and packaging: Laser cutting machines are used to cut and shape paper, cardboard, and other materials used in the printing and packaging industries.

5.6 Jewelry and art: Laser cutting is used to create intricate designs and shapes in precious metals and gems, as well as in other materials used in the creation of art.

These are just a few examples of the many applications of laser-cutting machines. The versatility of laser cutting makes it a valuable tool in a variety of industries and for a wide range of products and materials.

6. What Will Be The Growth Of The Laser Cutting Machine Market?

The global laser-cutting machine market is expected to grow significantly in the coming years. The market is driven by factors such as increasing demand from various end-use industries such as automotive, aerospace, and medical equipment, and growing demand for high precision and accuracy in cutting processes.

According to a market research report, the global laser cutting machine market is projected to grow at a CAGR (compound annual growth rate) of 6.5% from 2020 to 2025. The increasing demand for high-quality finished products, combined with the need for high efficiency and low cost, is expected to drive the growth of the market.

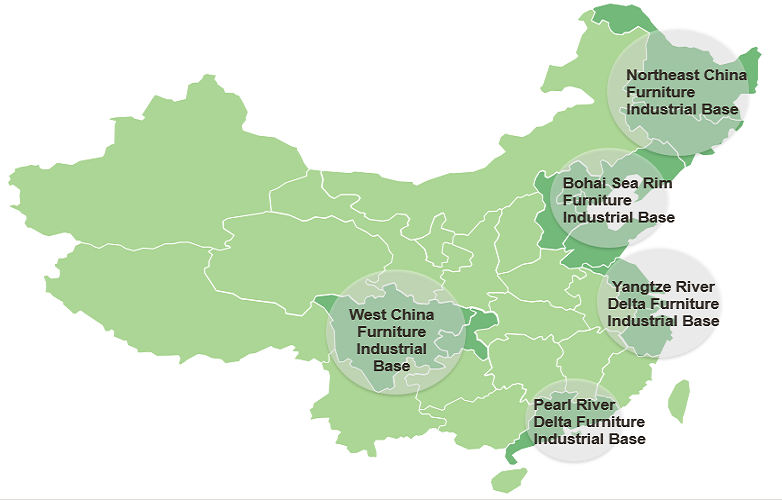

The Asia-Pacific region is expected to dominate the global laser cutting machine market due to the presence of a large number of manufacturers and increasing demand from various end-use industries such as automotive, construction, and electronics.

In conclusion, the growth of the laser cutting machine market is expected to remain strong in the coming years, driven by the increasing demand from various end-use industries, technological advancements, and the growing demand for high precision and accuracy in cutting processes.

7. Laser Cutting Machine Brand

All of the brands listed (Amada, Trumpf, Mitsubishi, Mazak, Bystronic, and HGTECH) are well-known manufacturers of laser-cutting machines. Each of these brands offers a range of laser-cutting solutions with different features and capabilities, so the best choice will depend on your specific requirements and budget.

7.1 Amada is a Japanese company that produces a wide range of metal fabrication equipment, including laser cutting machines.

7.2 Trumpf is a German manufacturer of laser cutting machines and other metal fabrication equipment. The company is known for its innovative technology and high-quality products.

7.3 Mitsubishi is a Japanese company that produces a range of laser cutting machines, as well as other industrial equipment. They have a good reputation for reliable and efficient machines.

7.4 Mazak is a Japanese company that produces a range of laser cutting machines, as well as other metal fabrication equipment. The company is known for its high-quality products and innovative technology.

7.5 Bystronic is a Swiss manufacturer of laser cutting machines and other metal fabrication equipment.

7.6 HGTECH is a Chinese manufacturer of laser cutting machines and other metal fabrication equipment. They offer cost-effective solutions for small- to medium-sized businesses..

8. What Are The Various Types Of Laser Cutting Machines?

Yes, these are some of the various types of laser-cutting machines. Here’s a brief overview of each:

8.1 3D laser cutting machines: These machines are used for cutting and shaping 3D objects, typically for prototyping and production purposes.

8.2 Laser Engraving Machines: These machines are used for engraving text, logos, images, and patterns onto a variety of materials such as metal, plastic, glass, and wood.

8.3 Solar Cell Cutting System: These systems are specifically designed for cutting and shaping photovoltaic cells used in solar panels.

8.4 Laser Cleaning System: These machines use laser technology to remove dirt, corrosion, rust, and other impurities from surfaces.

8.5 Laser tube cutting machines: These machines are used to cut tubes, pipes, and cylindrical objects into various shapes and sizes.

8.6 Punch laser machines: These machines combine traditional punching and laser cutting processes to create complex shapes in metal sheets.

8.7 Laser, Optics, and Accessories: This category includes various components, accessories, and consumables used in laser cutting machines, such as laser modules, lenses, mirrors, and more.

9. How To Use Laser Cutting Machine?

Laser-cutting machines are used to cut materials such as metals, plastics, and wood using a high-powered laser. The laser beam is directed onto the material being cut, which is melted or burned away, leaving a clean and precise cut. Here are the steps for using a laser-cutting machine:

9.1 Prepare the material: Clean the surface of the material to be cut and make sure it is securely clamped or held in place.

9.2 Load the design file: The laser cutting machine is controlled by a computer program, which reads a design file that specifies the cutting path and laser power. The design file can be created using CAD software, such as AutoCAD or Inkscape.

9.3 Set the laser power and speed: The laser cutting machine has adjustable settings for laser power and speed. The right settings will depend on the material being cut and the desired results. The laser power should be set high enough to cut through the material, but not so high as to damage it. The speed should be set fast enough to get the job done in a reasonable amount of time, but not so fast that the laser burns or scorches the material.

9.4 Start the cut: Once the laser cutting machine is set up, it can be started. The laser beam will follow the path specified in the design file, cutting through the material as it goes. It is important to keep an eye on the machine and the material being cut to make sure everything is going smoothly.

9.5 Check the results: After the cut is complete, the machine will automatically stop. The results should be checked to make sure the cut is clean and precise. If there are any problems, the laser power and speed can be adjusted and the cut can be repeated.

Note: Always make sure to follow the manufacturer’s instructions and safety guidelines when using a laser cutting machine. This will help to ensure that the machine is used safely and effectively as well.

10. Where To Buy Laser Cutting Machine?

There are several options available to purchase laser-cutting machines. You can purchase them directly from the manufacturer or a distributor, or you can purchase them through an online platform such as the ones you have listed:

Alibaba.com

Made-in-China.com

Dhgate.com

GlobalSources.com

Aliexpress.com

Chinabrands.com

Hunter Sourcing – a China sourcing agent.

It is important to thoroughly research the seller, product specifications, and shipping details before making a purchase. It is also recommended to compare prices to ensure that you are getting a quality product.

In addition to online platforms, you can also find laser-cutting machines at trade shows and exhibitions. This can provide you with an opportunity to see the machines in person and talk to the manufacturer or seller directly.

11. How Do We Choose Laser Cutting Machine Manufacturers?

Choosing a laser cutting machine manufacturer involves considering several factors to ensure you make the best decision for your needs. Some of the key factors to consider include:

11.1 Research and Development (R&D): The manufacturer should have a strong R&D team to continuously improve and innovate their laser cutting technology.

11.2 Solutions: The manufacturer should offer a range of laser cutting solutions that are suitable for different materials and applications.

11.3 OEM (Original Equipment Manufacturer) support: Consider the manufacturer’s capability to provide OEM services, including customization and branding of the machine.

11.4 Standard manufacturing practices: The manufacturer should follow industry-standard manufacturing practices to ensure the quality and performance of their machines.

11.5 Good Quality: The manufacturer should have a reputation for producing high-quality machines that are reliable and durable.

11.6 Machine performance: The laser cutting machine should perform optimally, be efficient, and meet the requirements of your specific application.

11.7 Quality guarantee: The manufacturer should provide a warranty for their machines to protect your investment and ensure long-term performance.

11.8 Training: The manufacturer should offer training and support to help you get the most out of your machine, including maintenance, operation, and software.

11.9 Certifications: The manufacturer should have the necessary certifications, such as ISO 9001, CE, and others, to show their commitment to quality and safety.

11.10 Service: The manufacturer should have a strong after-sales service team that can provide prompt and efficient support for your machine in case of any issues.

By considering these factors, you can select a laser cutting machine manufacturer that will provide you with a high-quality machine that meets your specific needs and requirements.

12. Import Laser Cutting Machine from China FAQ

Importing a laser-cutting machine from China involves customs, taxes, shipping, and quality assurance. Professional guidance can ensure a smooth and successful process.

12.1: Why import a laser cutting machine from China?

China is a major manufacturer of laser cutting machines and is known for producing high-quality machines at competitive prices. Additionally, the Chinese government provides subsidies and tax incentives to support the country’s manufacturing sector, which can translate into lower prices for consumers.

12.2: What are the payment terms when importing a laser cutting machine from China?

Payment terms can vary depending on the supplier and the terms of the agreement. Common payment options include wire transfers, letters of credit, and escrow services. It’s important to agree on the payment terms with the supplier before making the purchase to avoid any misunderstandings or disputes

12.3: How long does it take to import a laser cutting machine from China?

The time it takes to import a laser-cutting machine from China can vary depending on factors such as the shipping method, customs clearance, and the distance between the two countries. On average, it can take 4-8 weeks for the machine to be shipped and delivered.

12.4 Which laser cutting is better, CO2 or fiber?

The choice between CO2 and fiber laser cutting depends on the specific application and requirements. Both have their own strengths and weaknesses.

CO2 laser cutting is the traditional method and has been used for many years in a wide range of cutting applications. It is best suited for cutting non-metallic materials such as wood, paper, cardboard, and plastic. CO2 lasers are also relatively inexpensive compared to fiber lasers.

Fiber laser cutting, on the other hand, is a more recent technology and is known for its high power efficiency and exceptional cutting quality, particularly on metal materials. It is often the preferred choice for cutting metals such as stainless steel, aluminum, and copper. Fiber lasers are also more durable and require less maintenance compared to CO2 lasers.

In summary, CO2 lasers are best for cutting non-metallic materials, while fiber lasers are ideal for cutting metal. If you’re unsure about which one to choose, it’s always best to consult with a laser-cutting expert or manufacturer to determine the best solution for your specific needs..

12.5 How to maintain a fiber laser cutter?

To maintain a fiber laser cutter, it is recommended to follow the following steps:

1. Clean the Machine Regularly: Dust and debris can accumulate on the laser and optics, so it is important to clean the machine regularly to prevent damage.

2. Keep the Lens Clean: The lens is one of the most critical components of a fiber laser cutter, so it is important to keep it clean. Clean the lens after each use, and replace it if it becomes damaged or dirty.

3. Maintain Proper Cooling: Fiber laser cutters use a cooling system to keep the laser and optics cool, so it is important to maintain the cooling system and keep it free of debris and contaminants.

4. Check Alignments: Check the laser head alignment regularly to ensure that it is properly aligned with the workpiece. Improper alignment can lead to a decrease in laser cutting performance and accuracy.

5. Monitor the Laser Power: Monitor the laser power regularly to ensure that it is consistent and within the manufacturer’s specifications. A drop in laser power can indicate a problem with the laser or optics.

6. Check the Focus: Check the focus regularly to ensure that the laser beam is properly focused on the workpiece. Improper focus can lead to a decrease in cutting performance and accuracy.

7. Check for Leaks: Check the laser and cooling system for leaks regularly, and repair any leaks as soon as possible to prevent damage to the machine.

8. Replace Worn Parts: Replace any worn parts, such as the laser head, mirrors, or lens, as soon as possible to ensure optimal laser cutting performance and accuracy.

It is important to follow the manufacturer’s guidelines and to have a maintenance schedule in place to ensure that the fiber laser cutter is properly maintained. Regular maintenance will help to extend the life of the machine and prevent costly repairs.

12.6 What are some disadvantages of laser cutting?

Laser cutting is a precise and efficient method of cutting materials, but it also has some disadvantages that include:

1. Cost: Laser cutting machines are expensive to purchase and maintain, making them a costly process for small businesses or individual users.

2. Material restrictions: Some materials, such as reflective metals, cannot be cut with a laser due to the reflection of the laser beam.

3. Heat-affected zone: The laser cutting process generates heat, which can affect the material’s properties, such as its hardness and tensile strength, in the area around the cut.

4. Material thickness limitations: While laser cutting can handle a wide range of material thicknesses, there is a limit to the maximum thickness that can be cut effectively.

5. Toxic fumes: The laser cutting process can produce toxic fumes, particularly when cutting materials that contain hazardous chemicals or substances.

6. Operator skill level: The precision of laser cutting depends on the skill of the operator, as well as the quality and calibration of the laser cutting machine.

7. Slow cutting speed: Laser cutting can be slower than other cutting methods, such as plasma cutting, for thicker materials.

8. High energy consumption: Laser-cutting machines consume a large amount of electrical energy, which can increase operating costs and contribute to environmental issues.

13. Why Choose Huntersourcing As Your Laser Cutting Machine Sourcing Agent?

Huntersourcing is a reliable and experienced sourcing agent that provides a comprehensive range of laser-cutting machines. By choosing Huntersourcing as your sourcing agent, you can enjoy numerous benefits such as:

13.1 Access to a wide range of high-quality laser cutting machines from trusted manufacturers

13.2 Expert knowledge and advice on the latest technologies and products

13.3 Cost-effective solutions to meet your specific requirements

13.4 Seamless communication and coordination with suppliers, reducing the hassle and stress of sourcing

13.5 Hassle-free and smooth import process, including customs clearance and shipping

If you are looking for a reliable and efficient sourcing agent for your laser cutting machine needs, look no further than Huntersourcing.

To get started, simply contact us today and let us know your specific requirements. Our team of experts will work closely with you to provide the best solution to meet your needs and budget.

Related Post

Furniture is a must for an office or a home. It is available at varying price points as Read more

Wood is extensively used in making furniture around the world. Wood can be molded in any shape or Read more

In the current market condition, a major portion of the world's consumption depends on China. The product range Read more

Contact Us Get Free Quote!

* Please kindly fill out the form for inquiry

* we will reply to your inquiry within 24hours